Competition Topography of Terror

Berlin

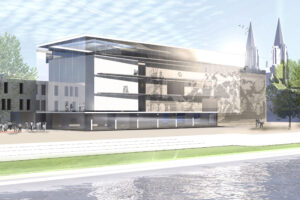

Topography of Terror refers to a site in the center of Berlin, now a scar in the city's layout.

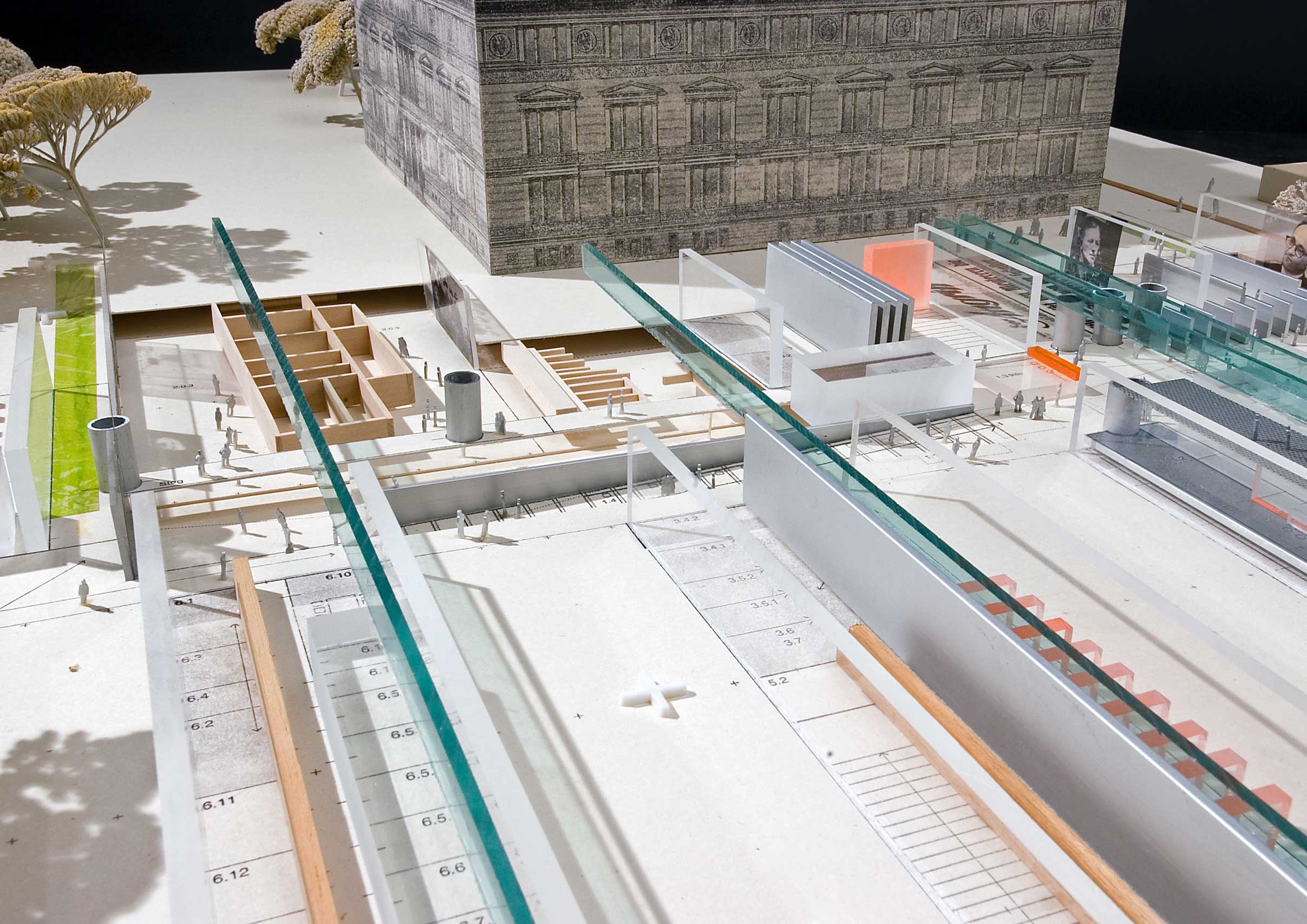

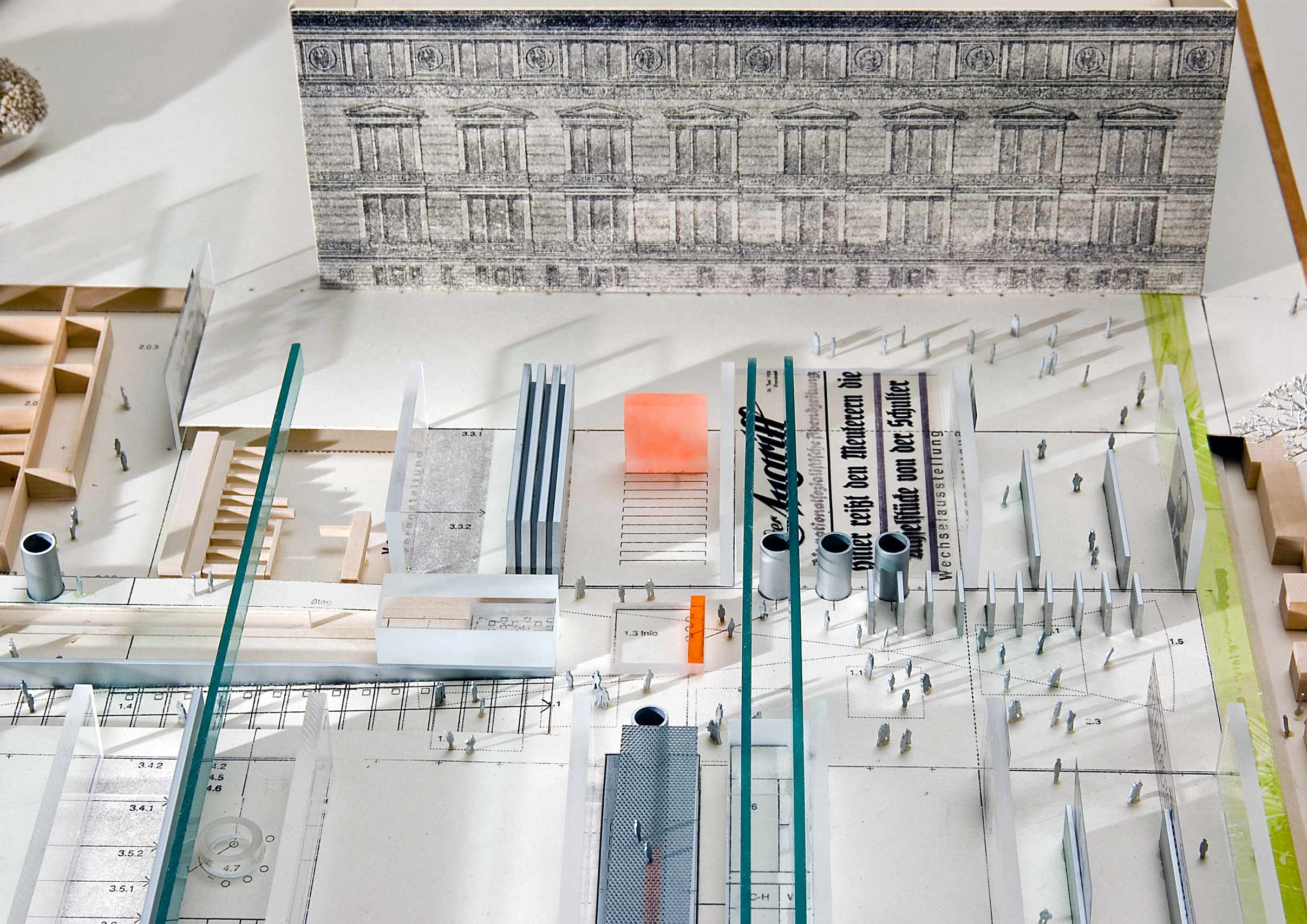

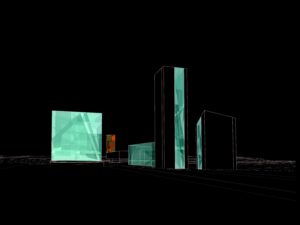

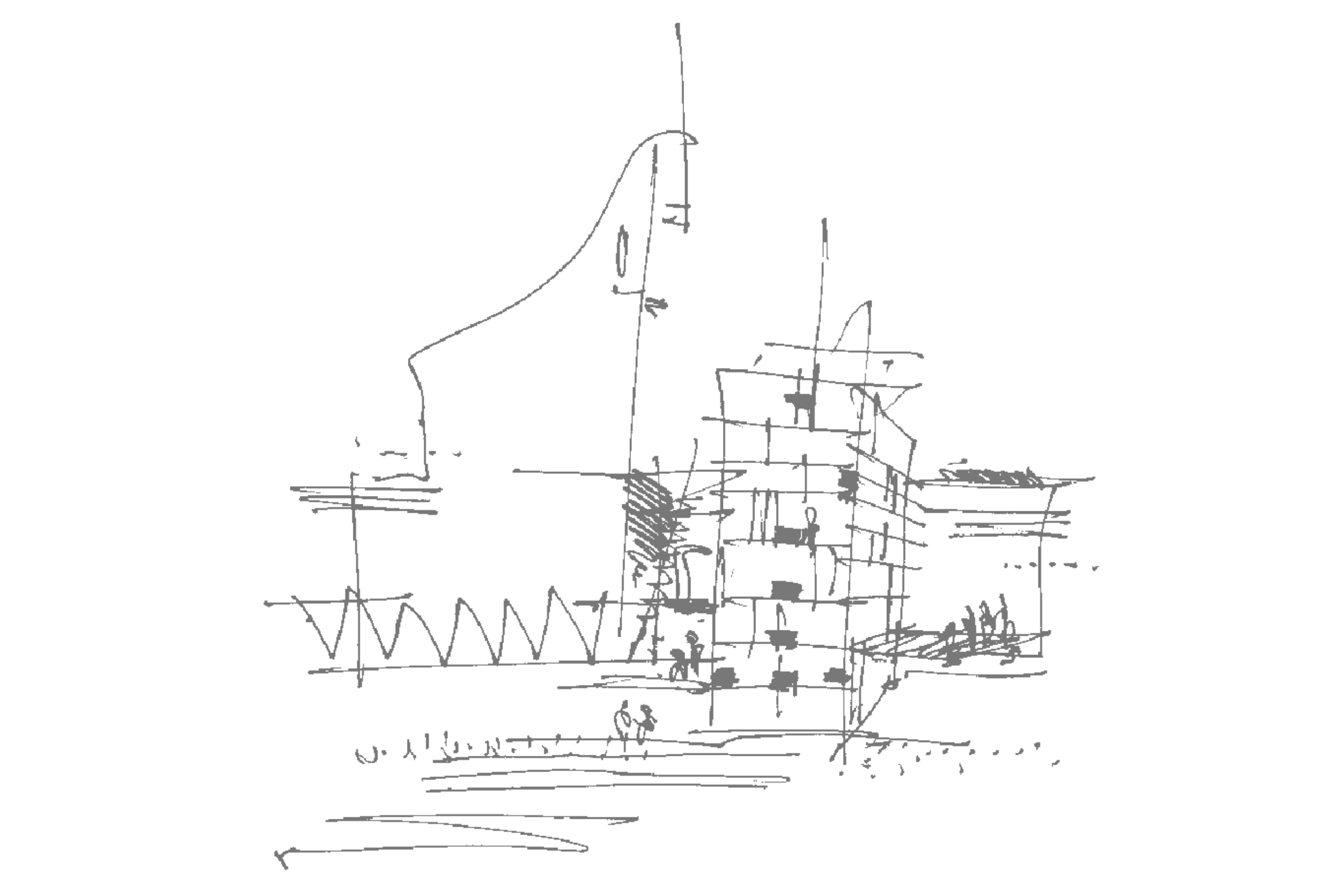

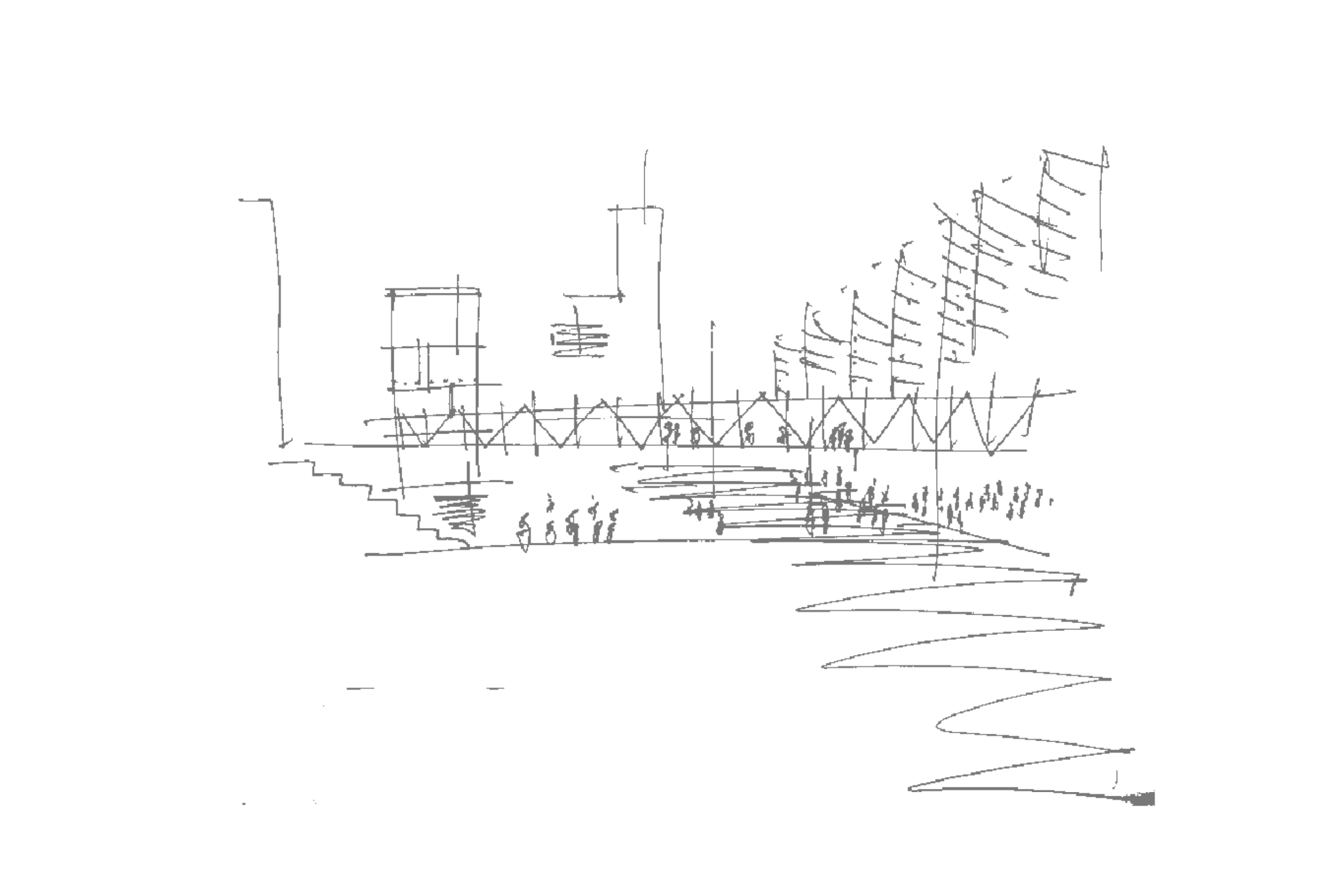

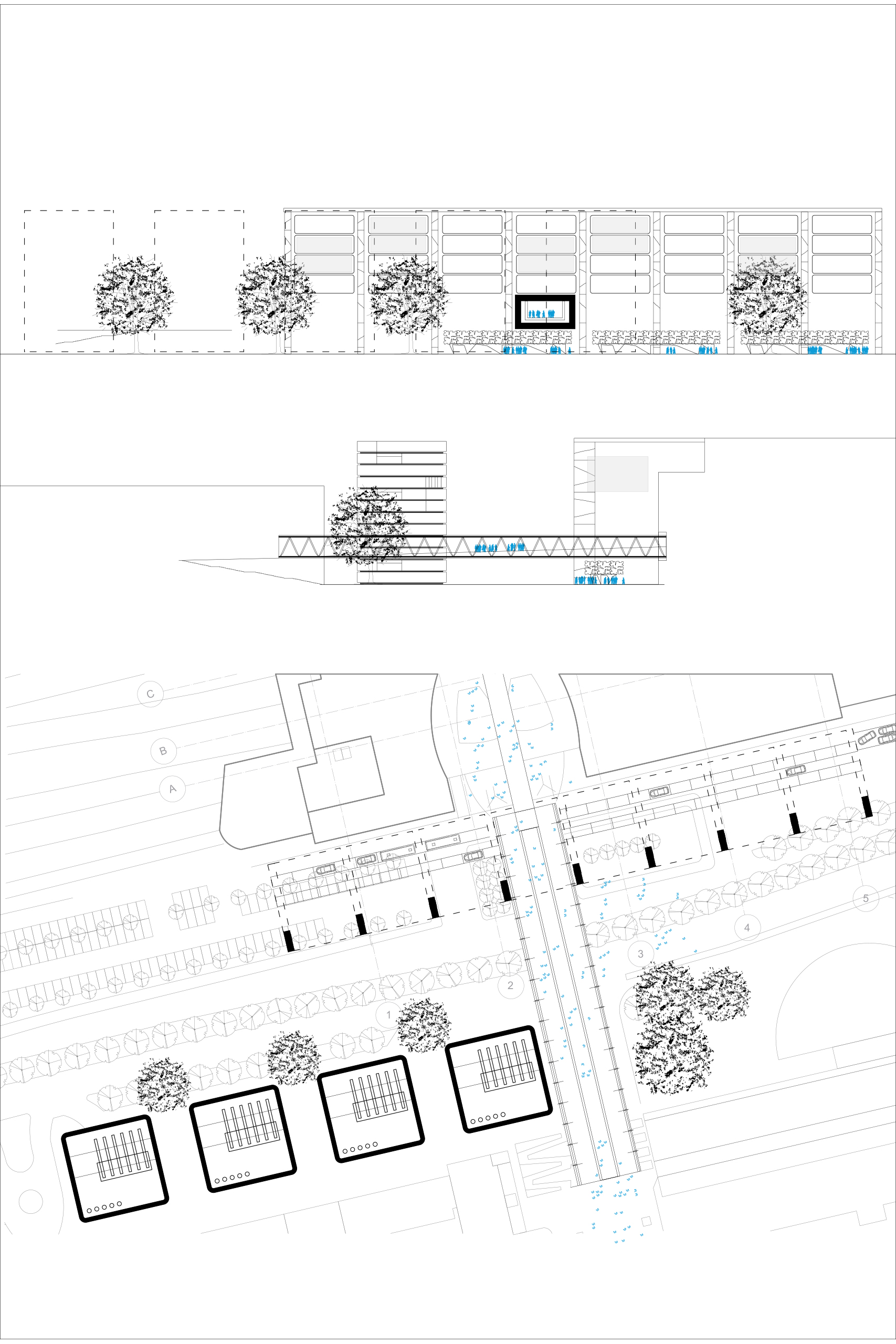

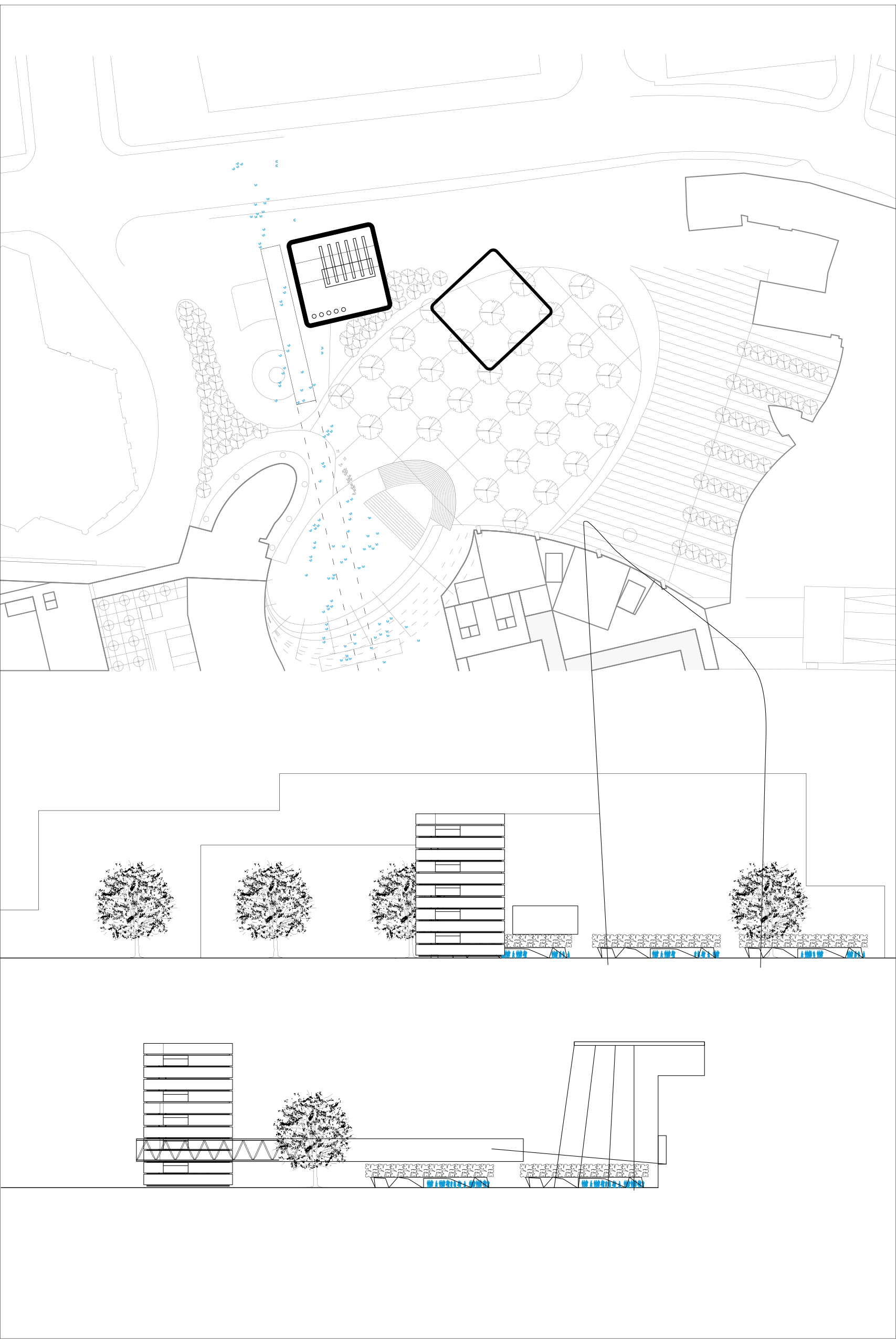

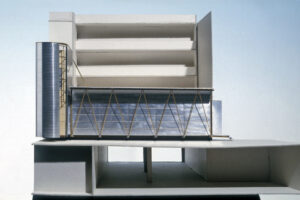

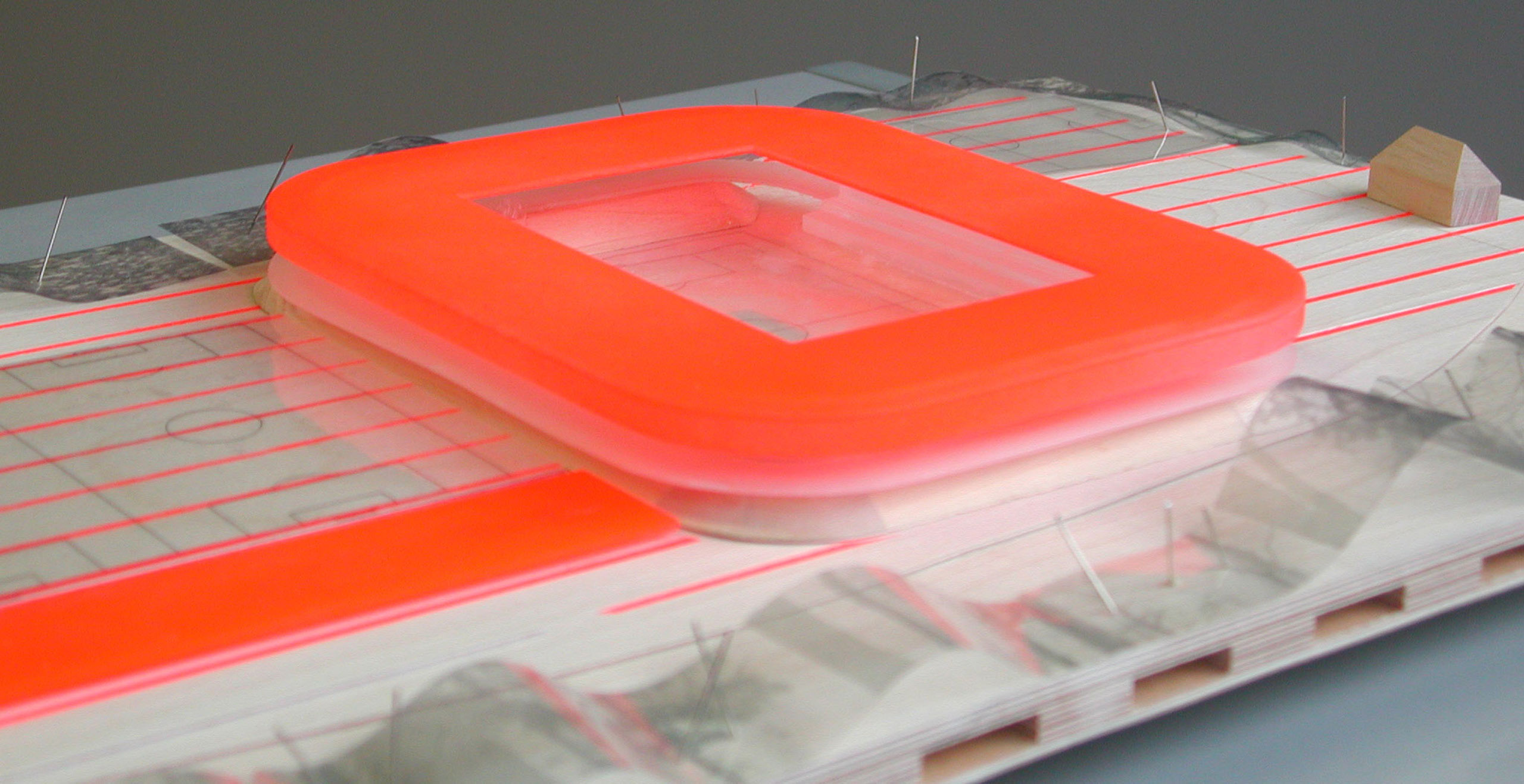

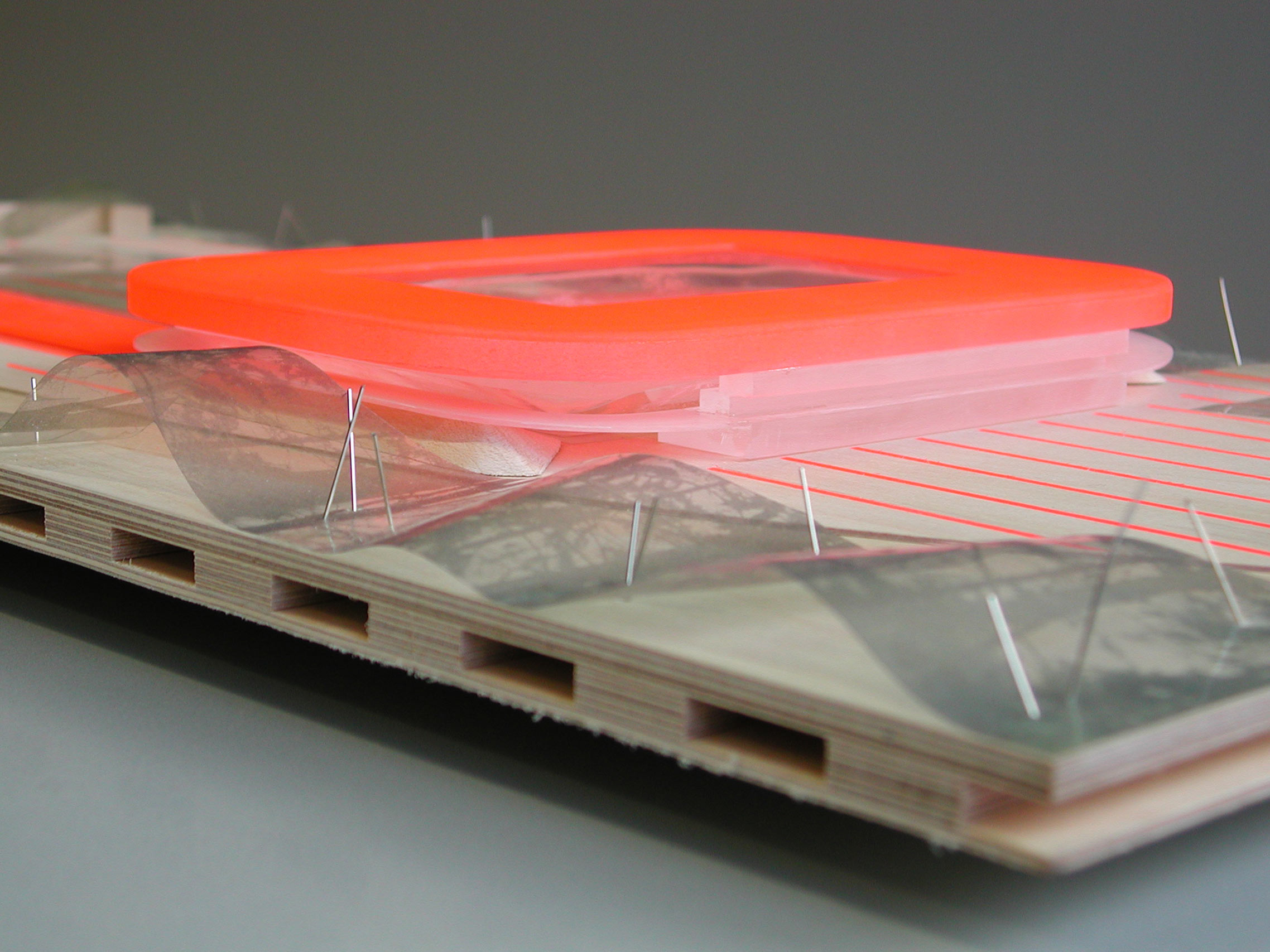

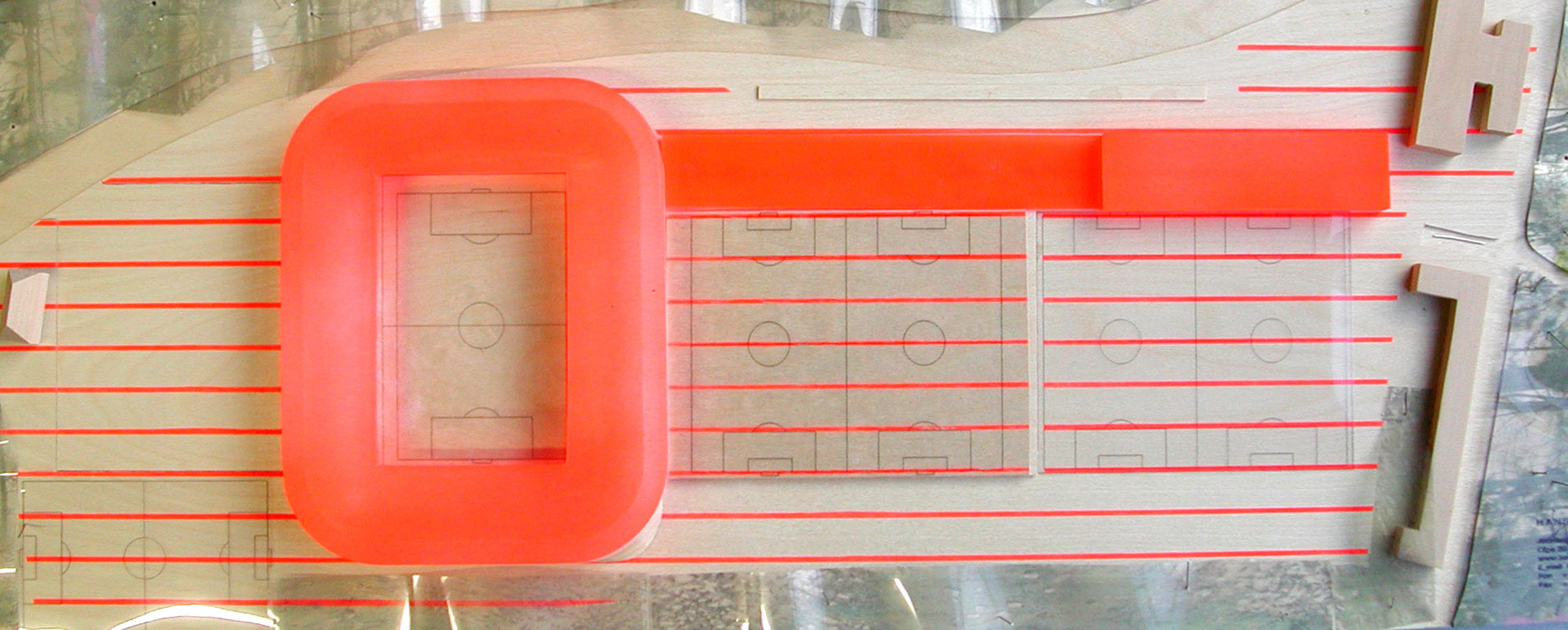

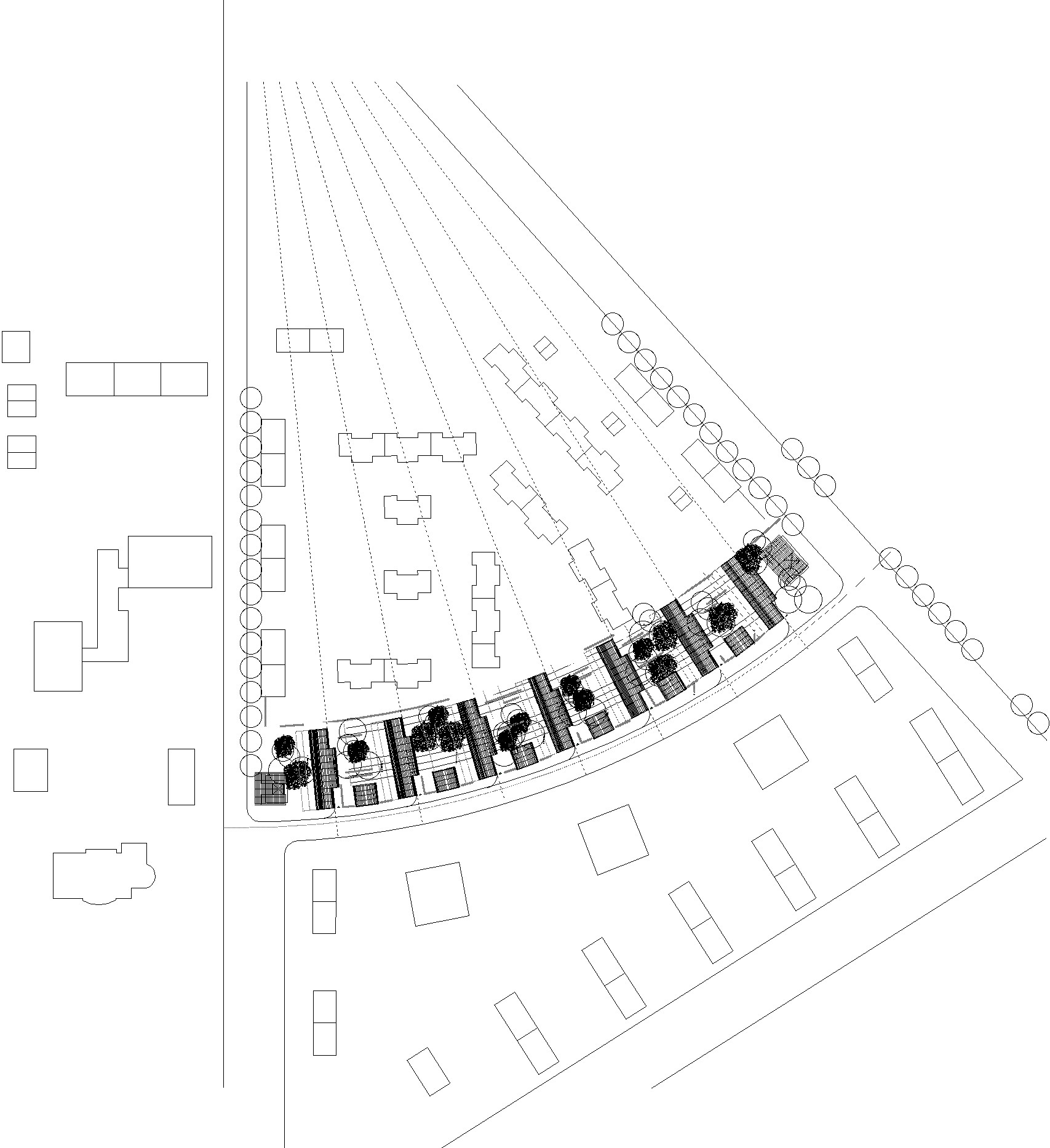

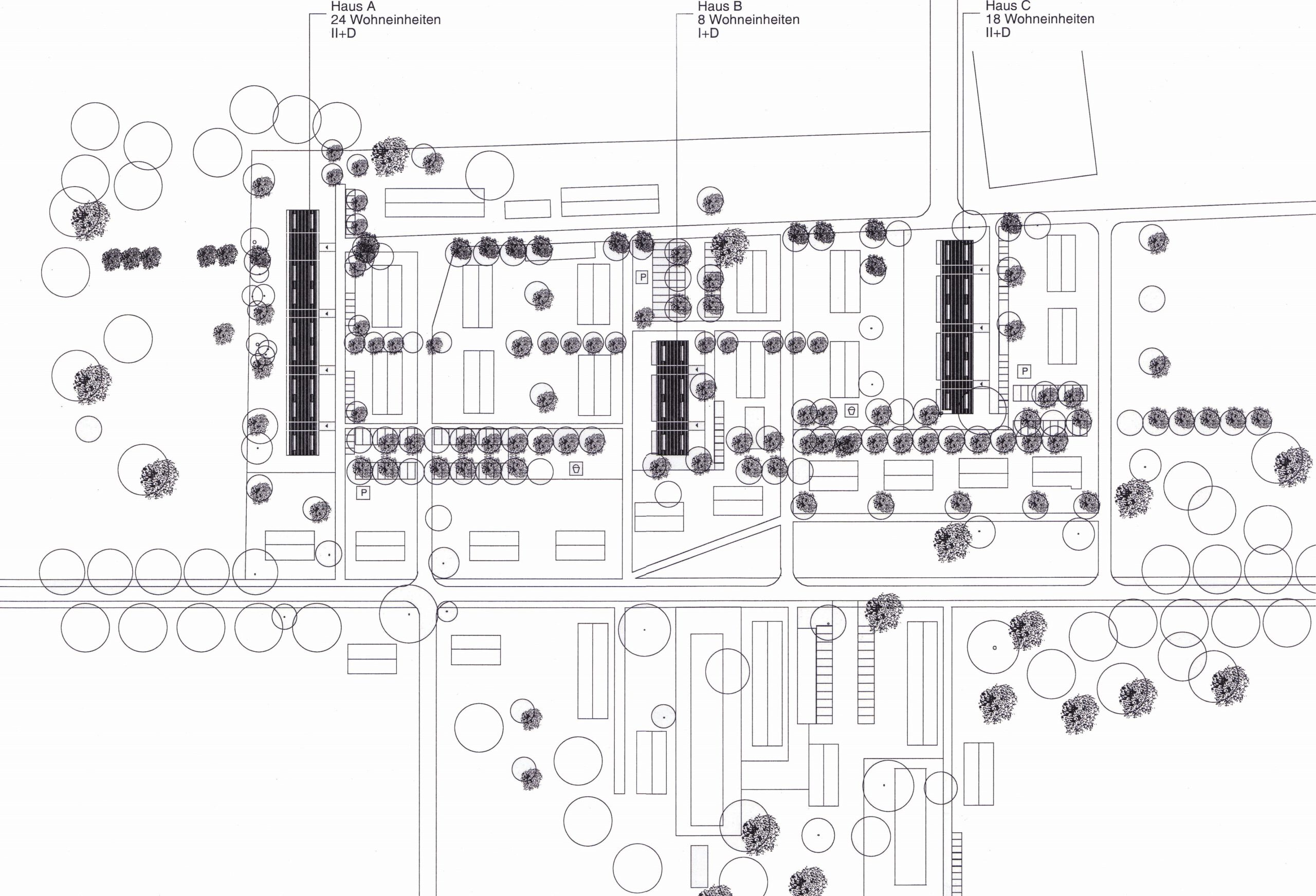

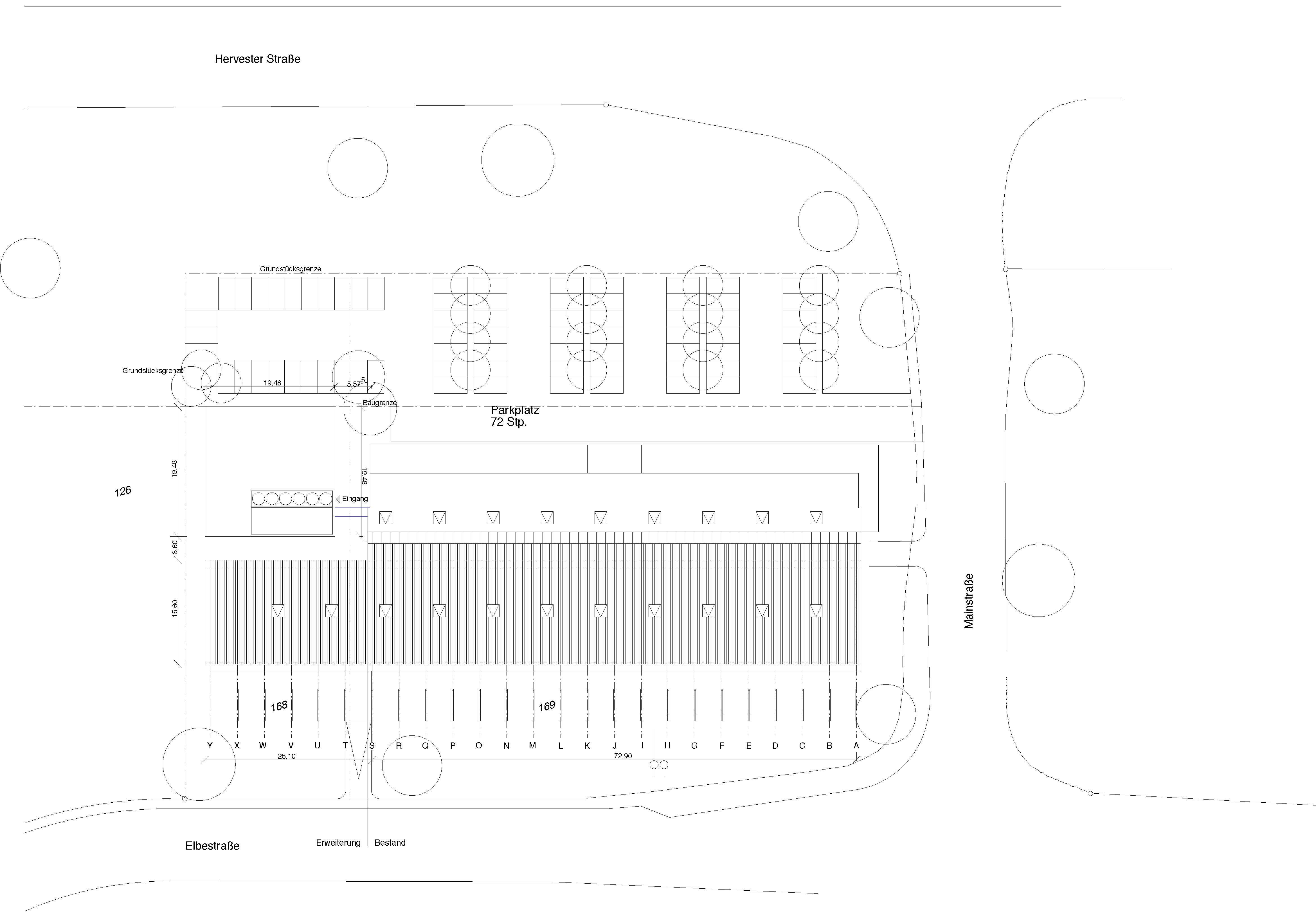

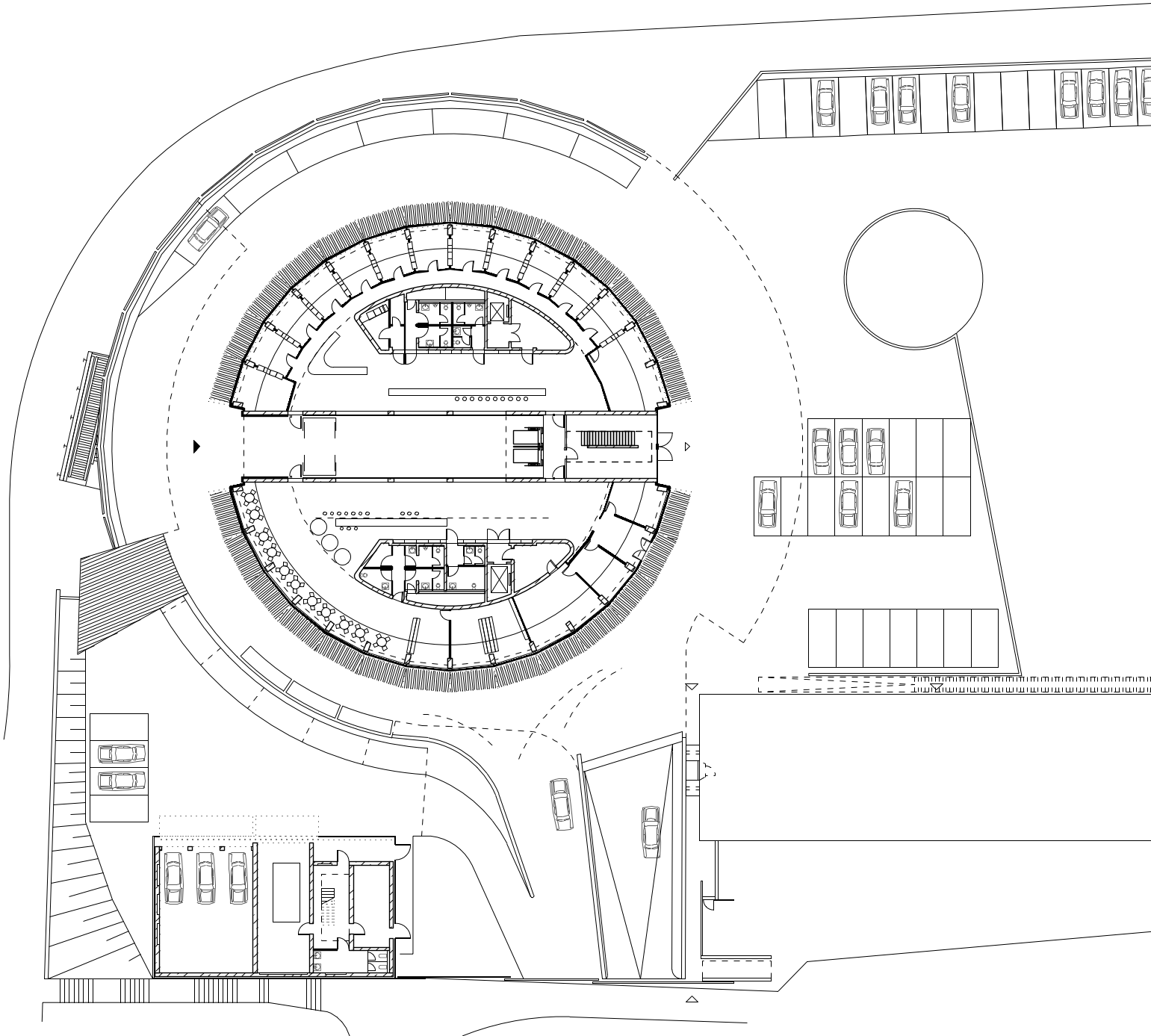

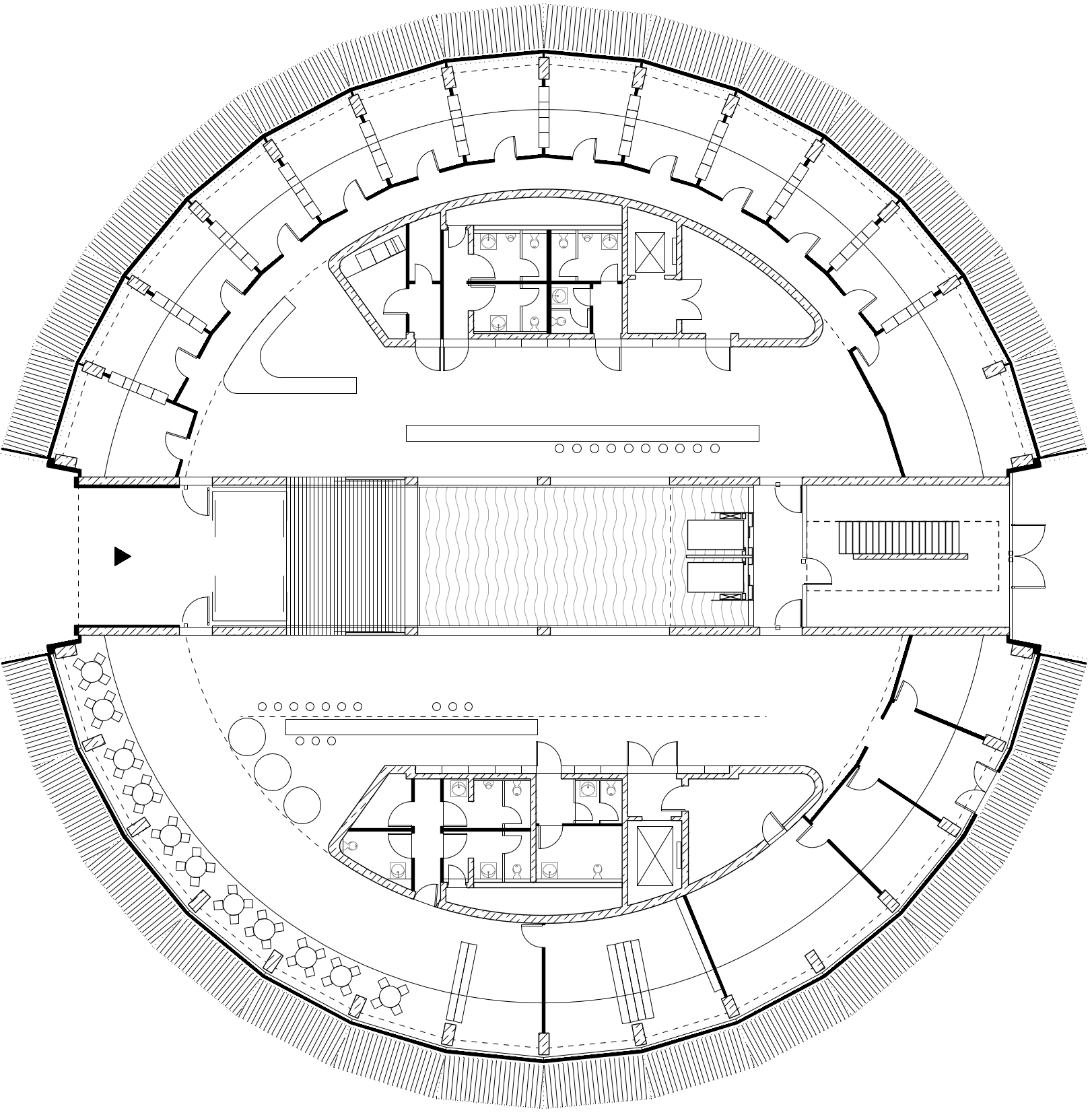

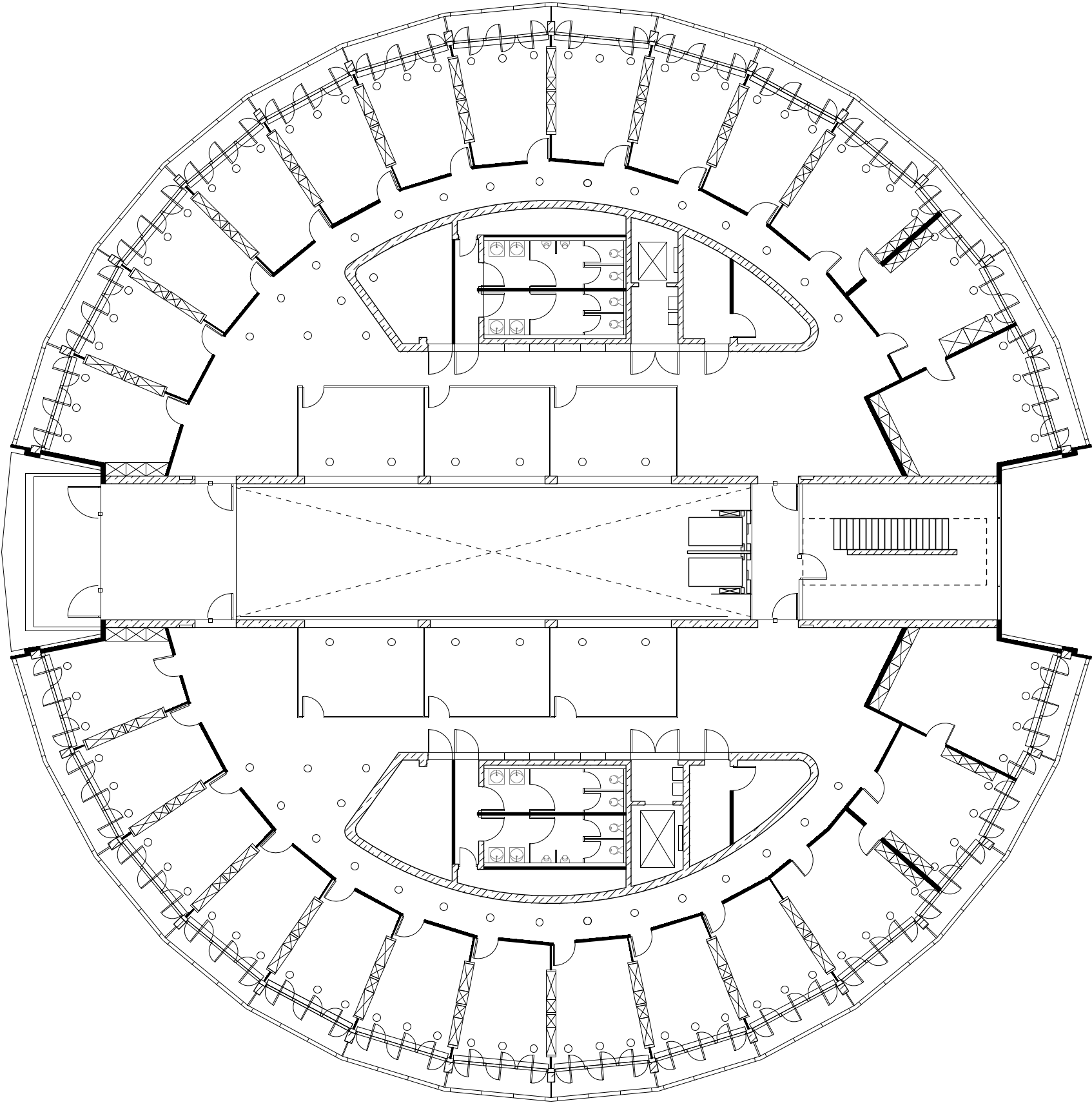

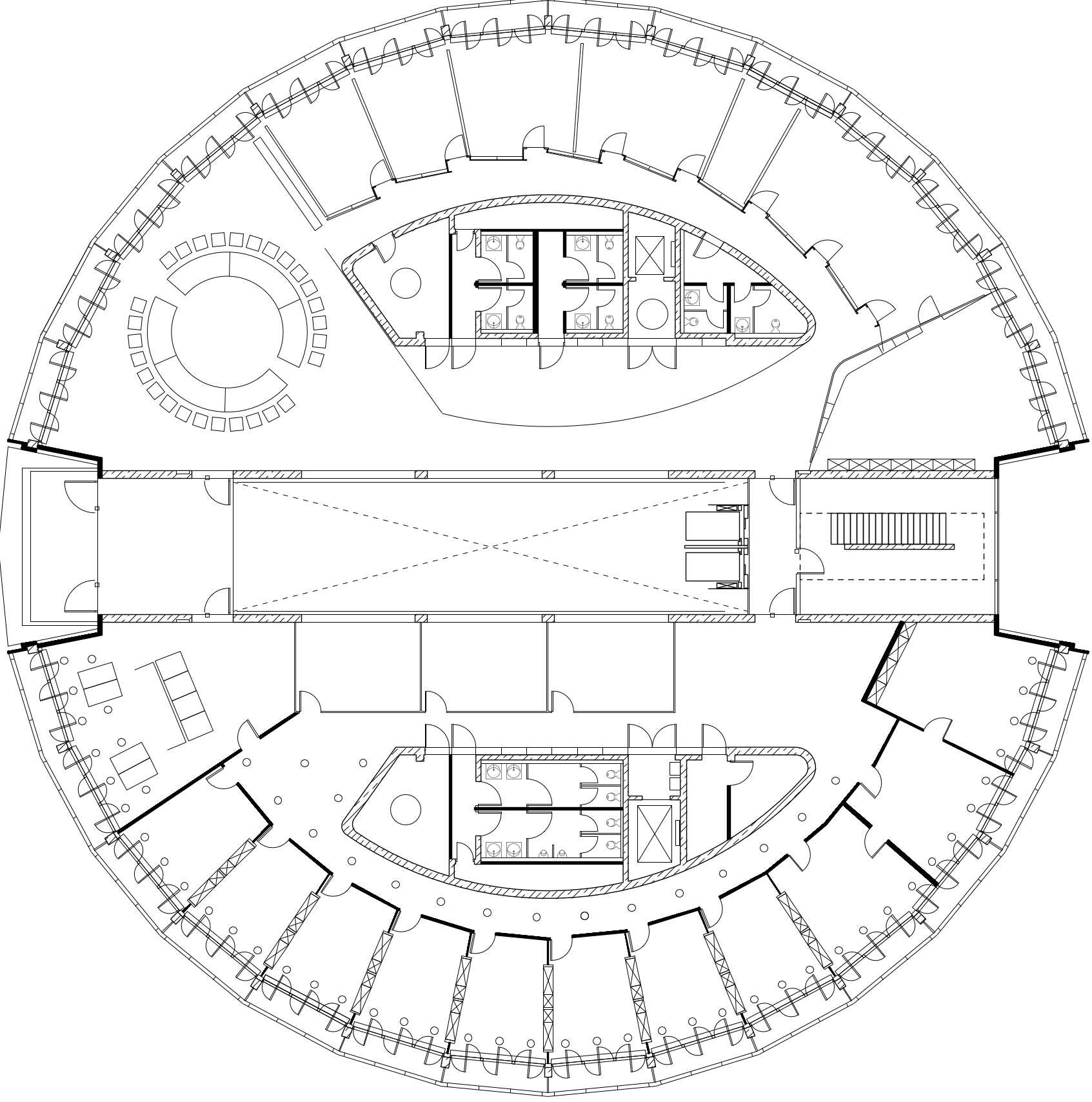

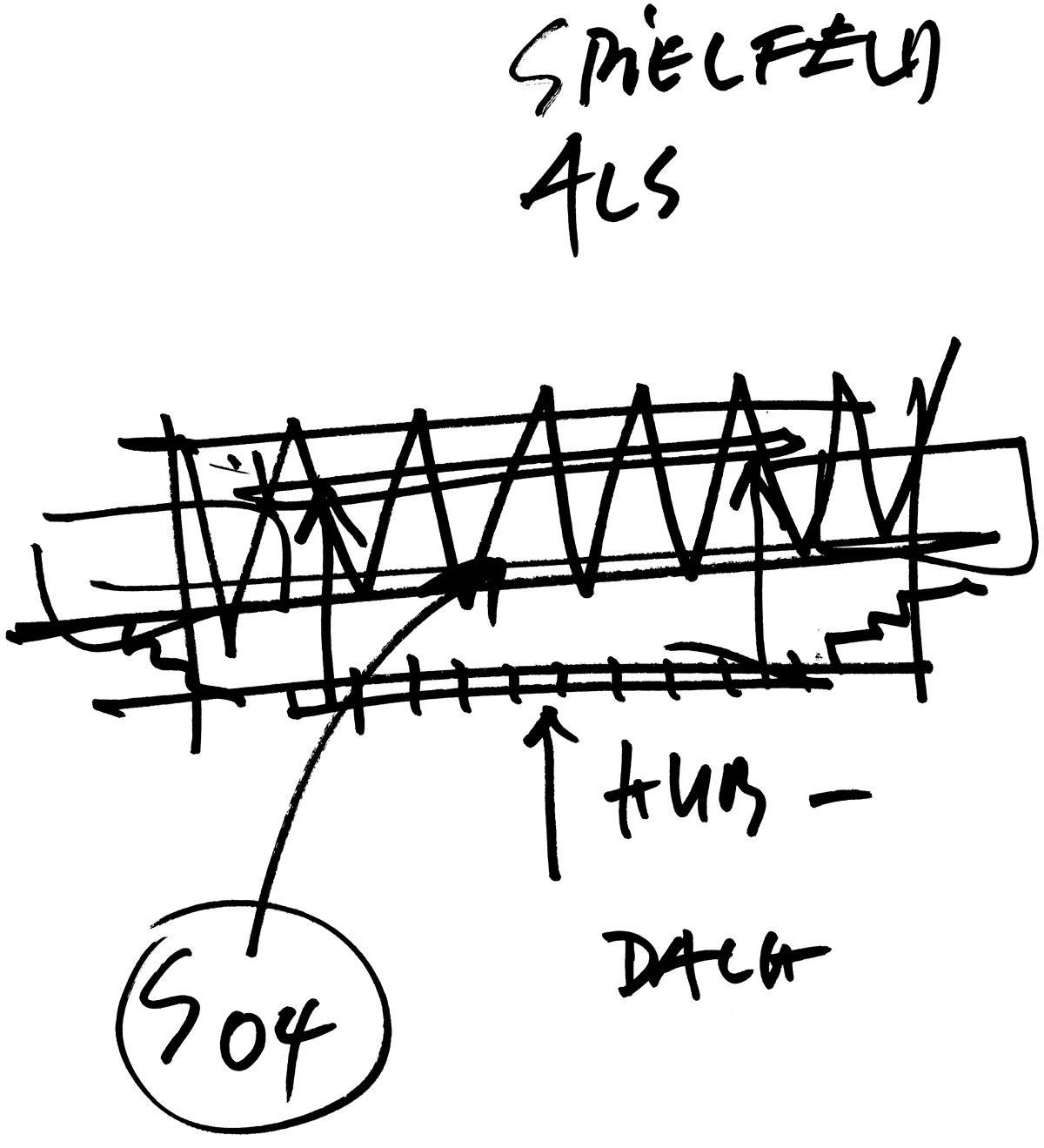

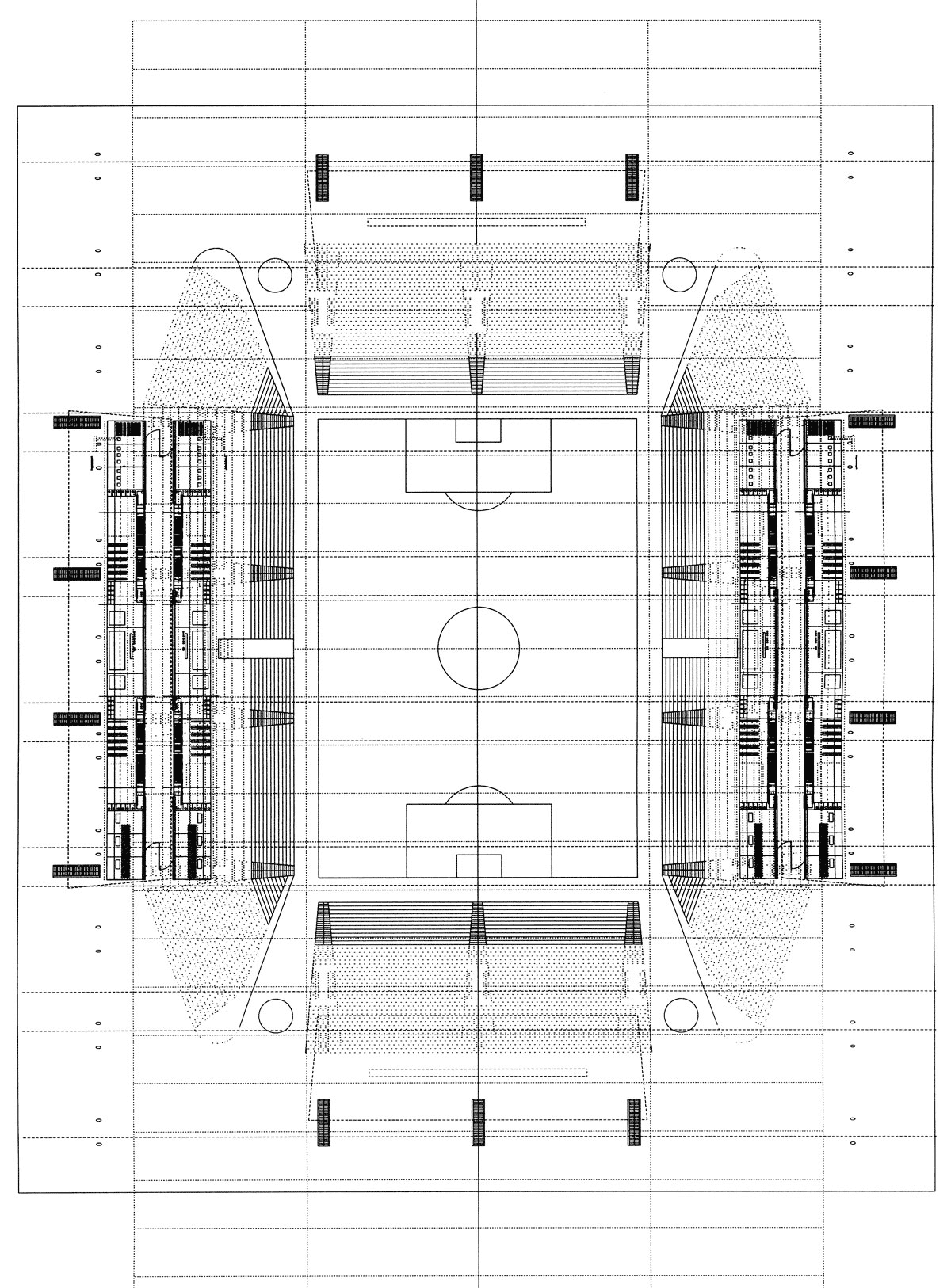

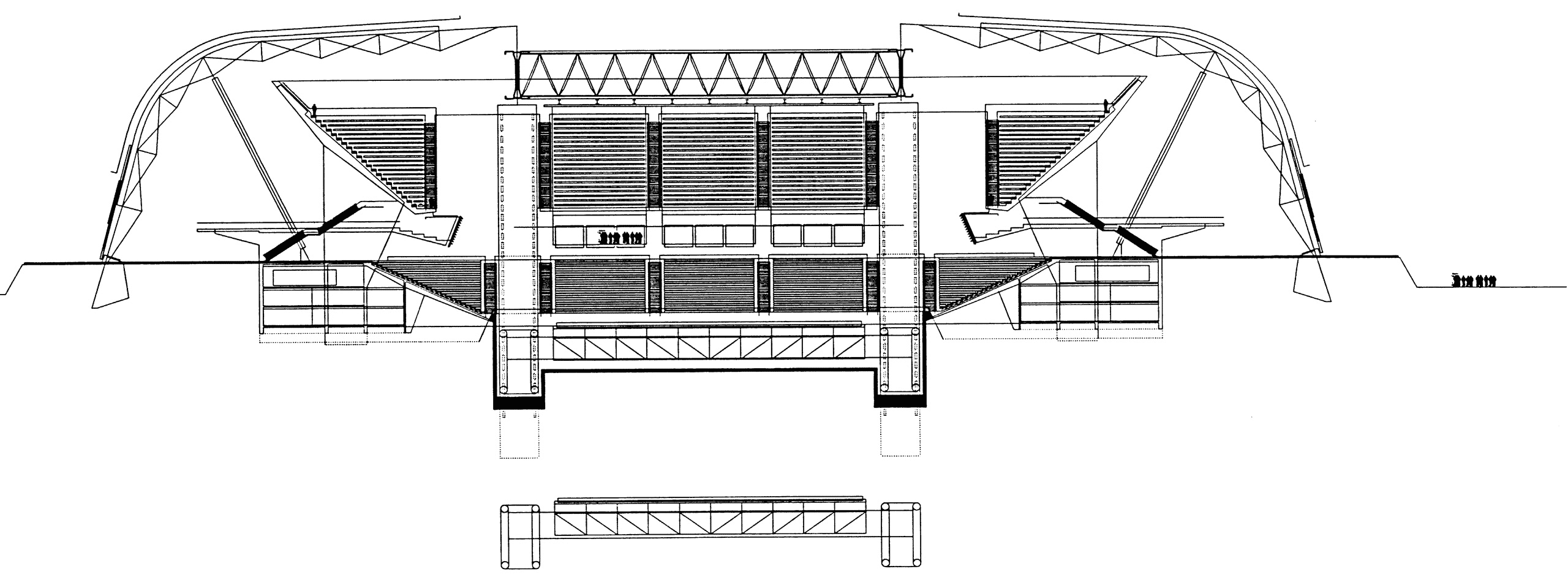

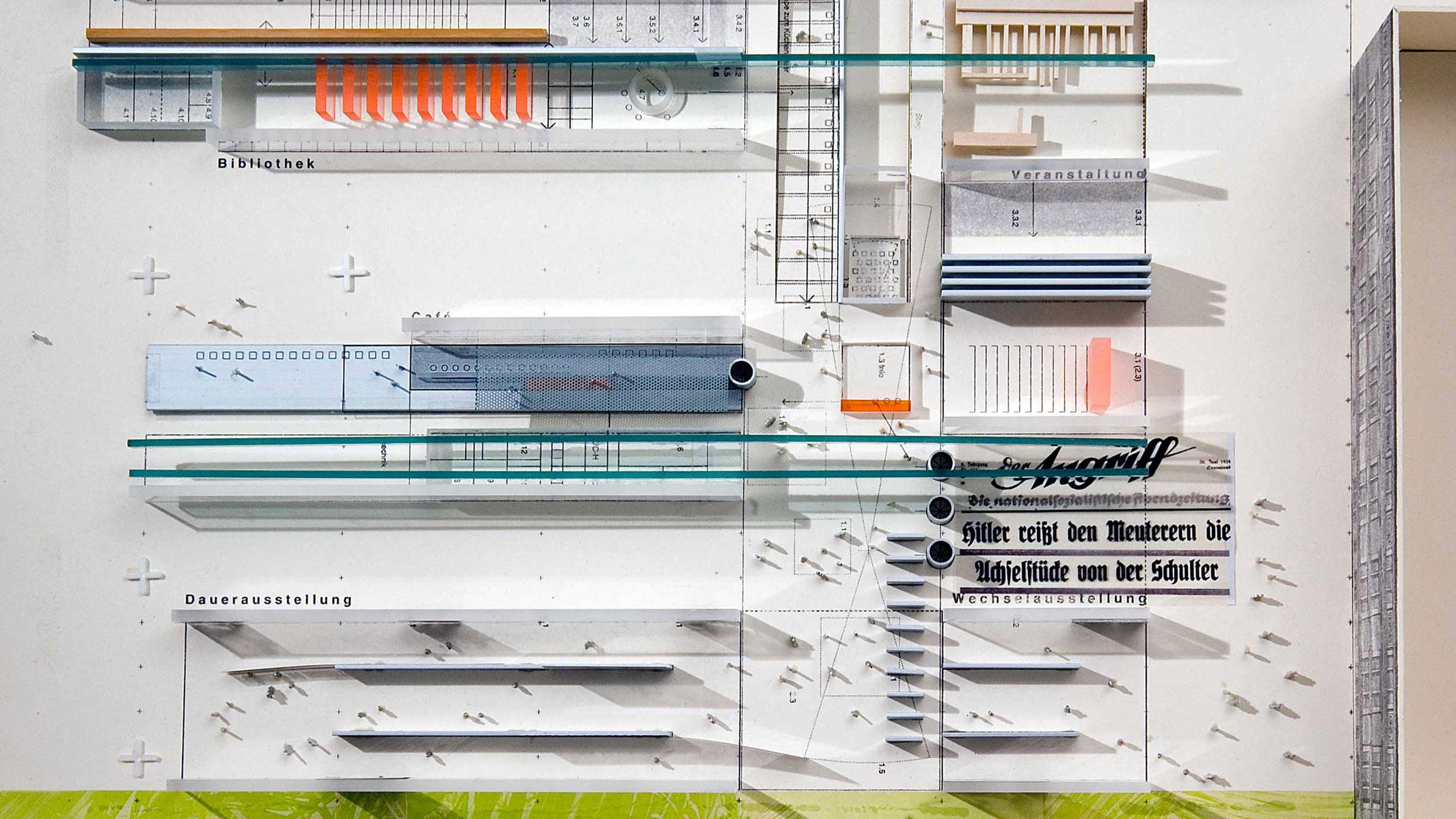

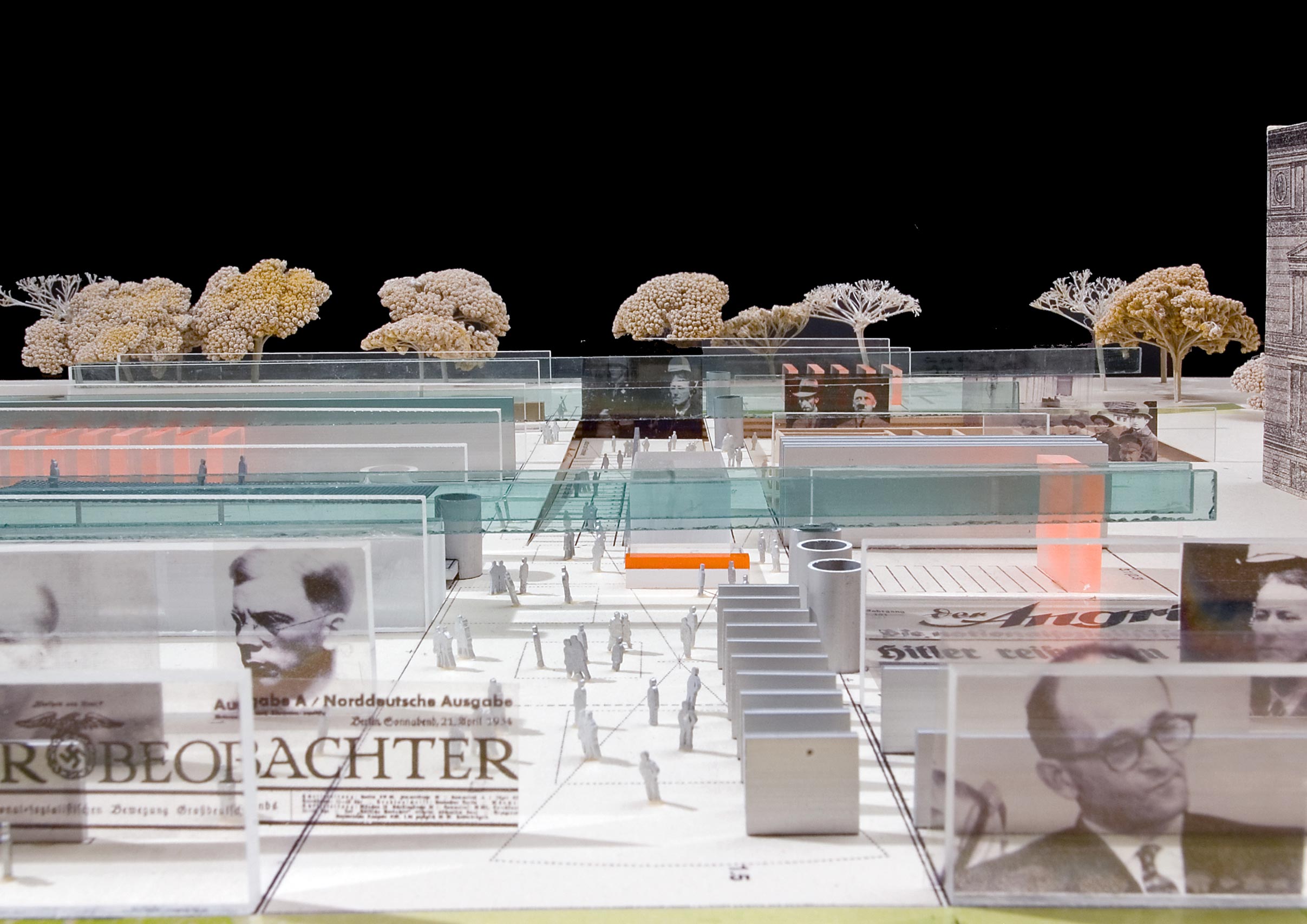

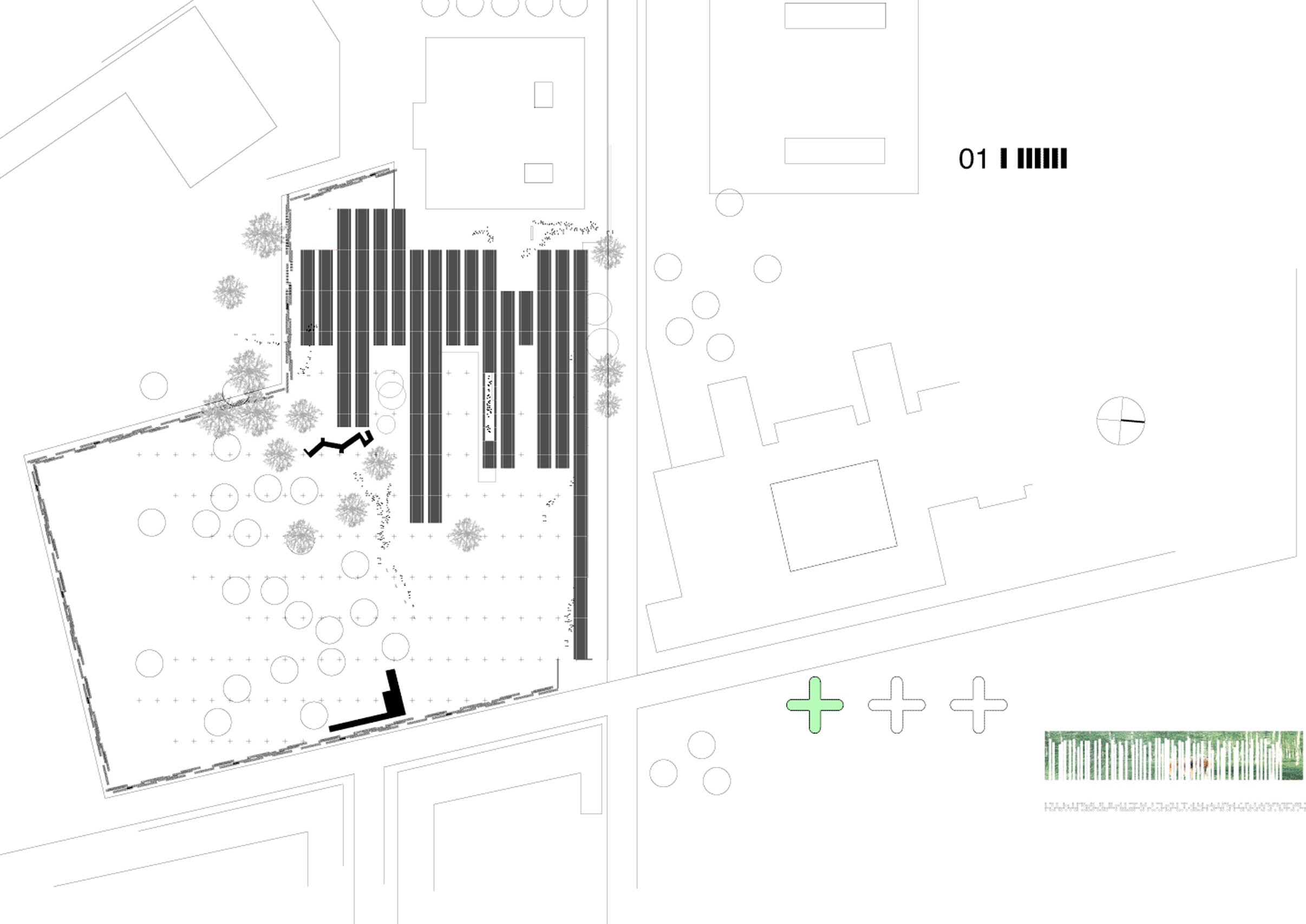

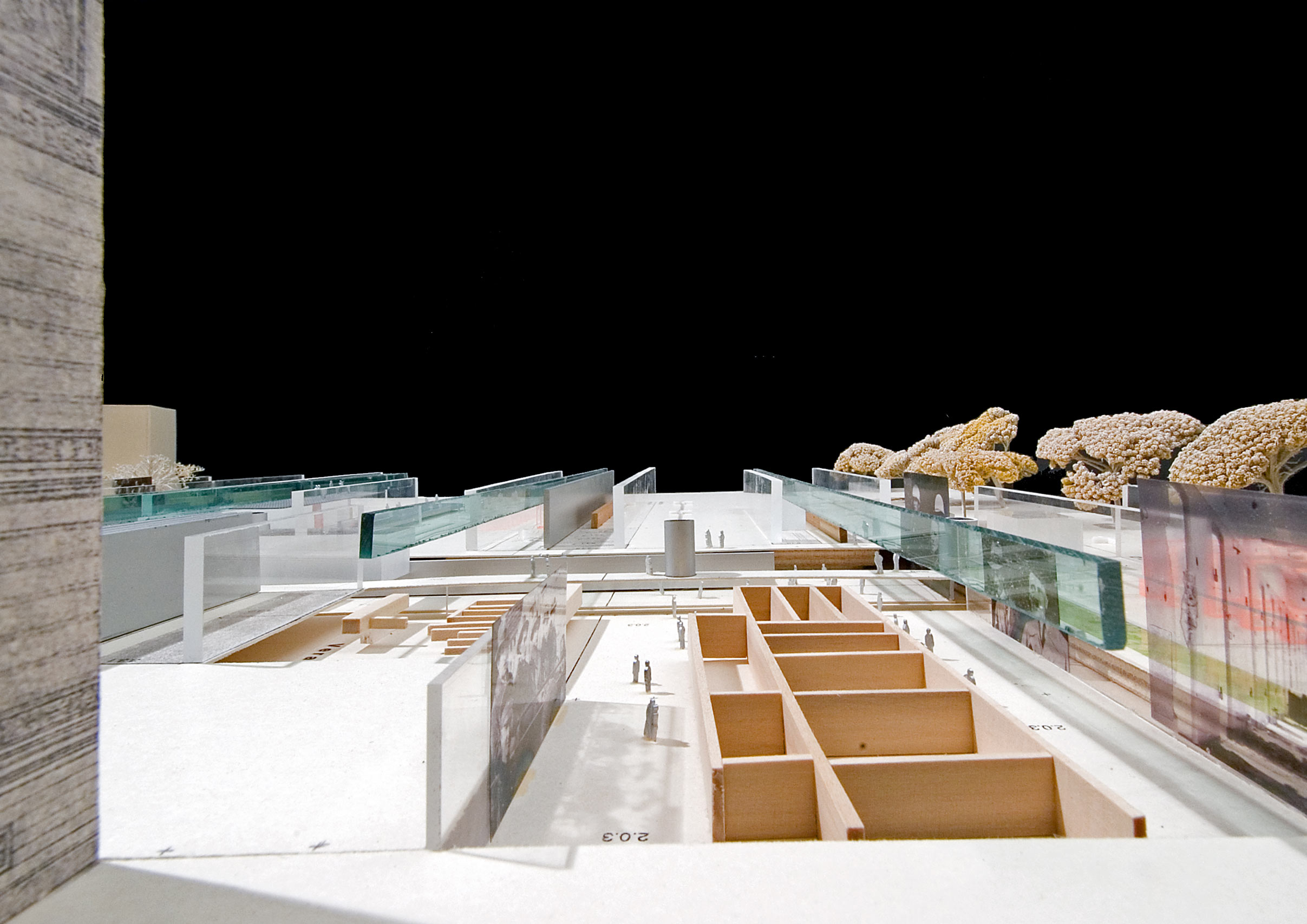

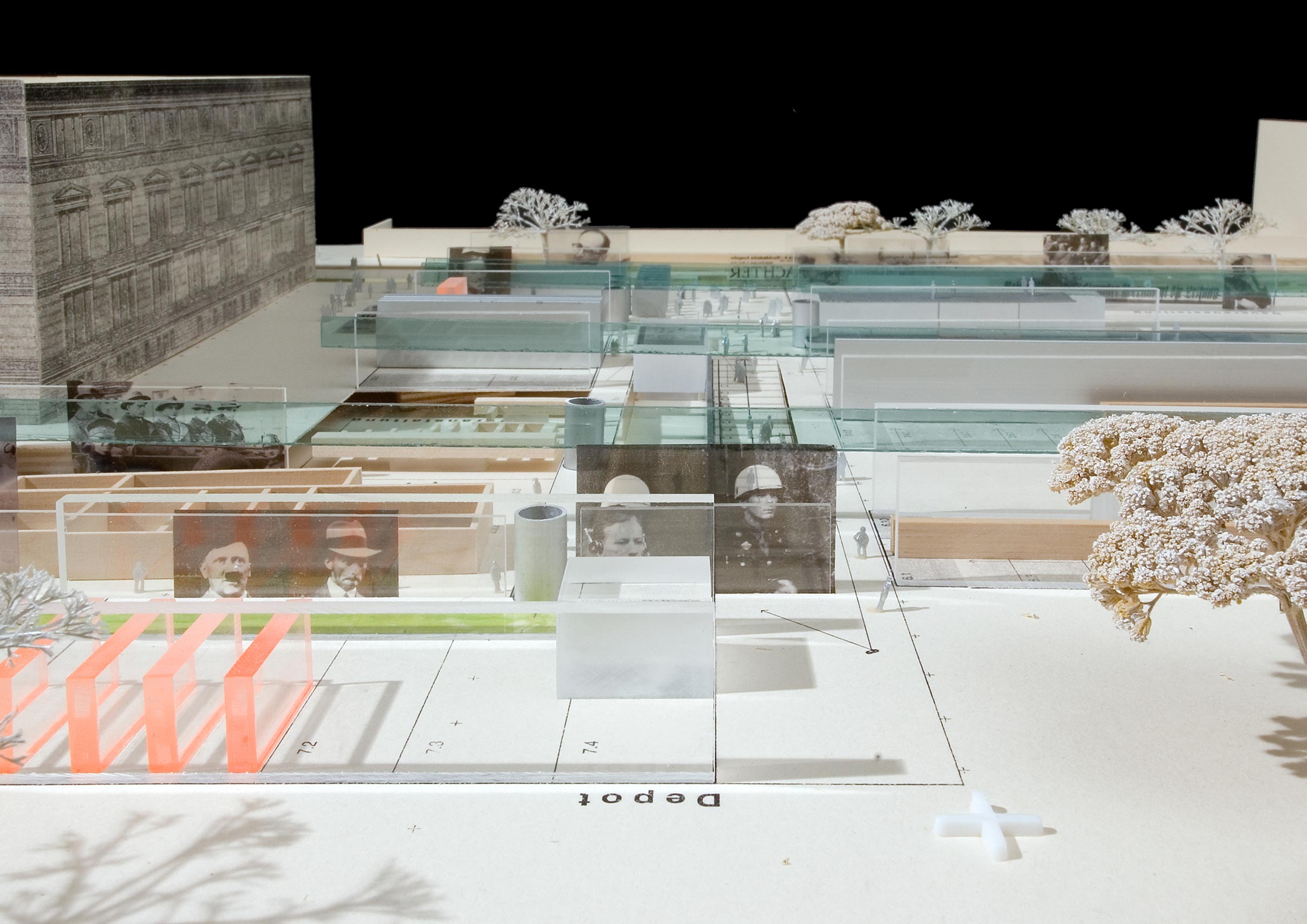

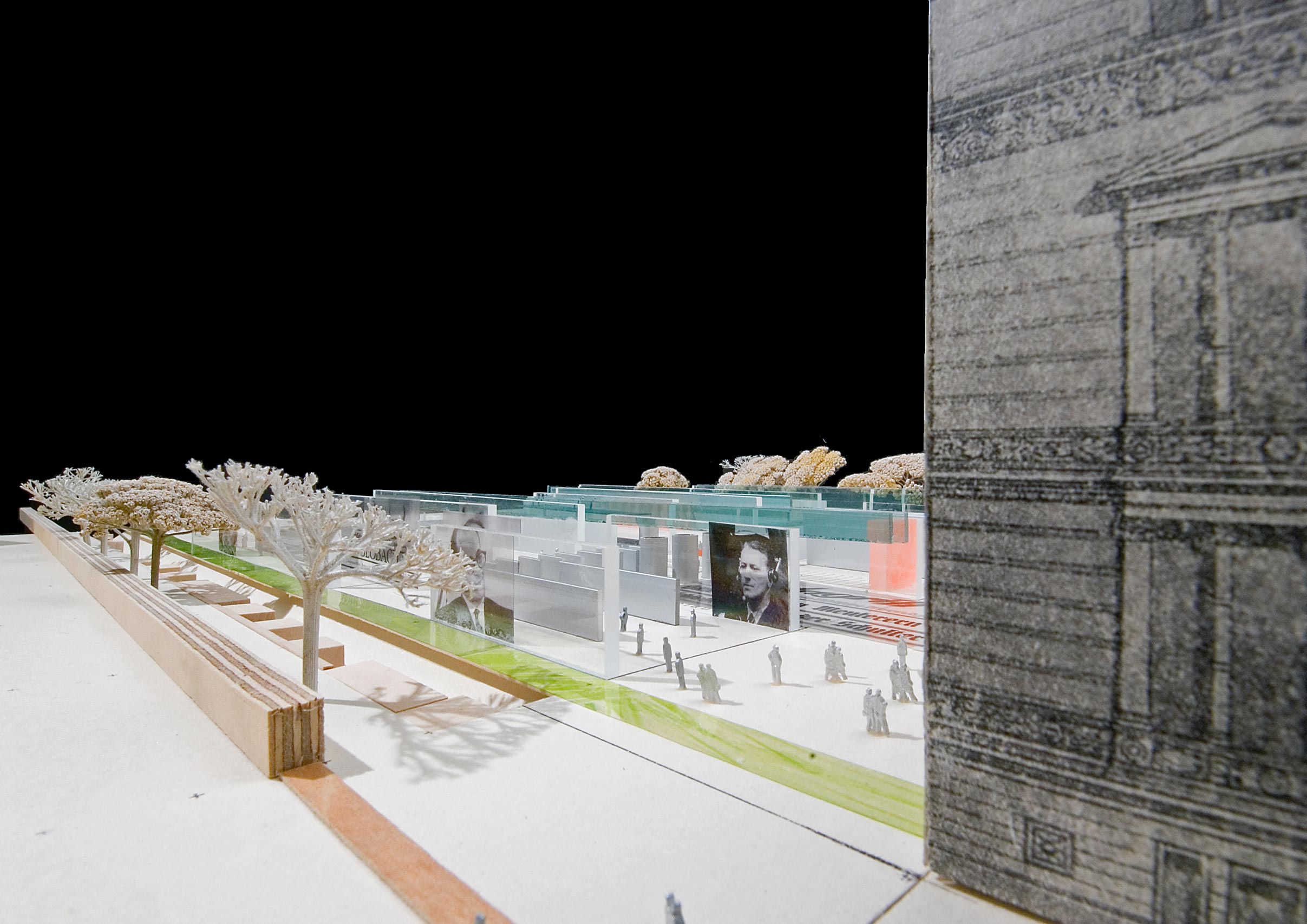

We understand this site as an archaeological search field (archaeology of history). Therefore, we propose using a construction form that can be temporary, follows future excavations, and integrates new findings into the building structure: a systematically designed excavation site organized as a "Matrix"—a system of mathematical dimensions arranged in a schema of horizontal rows and vertical columns (Brockhaus).

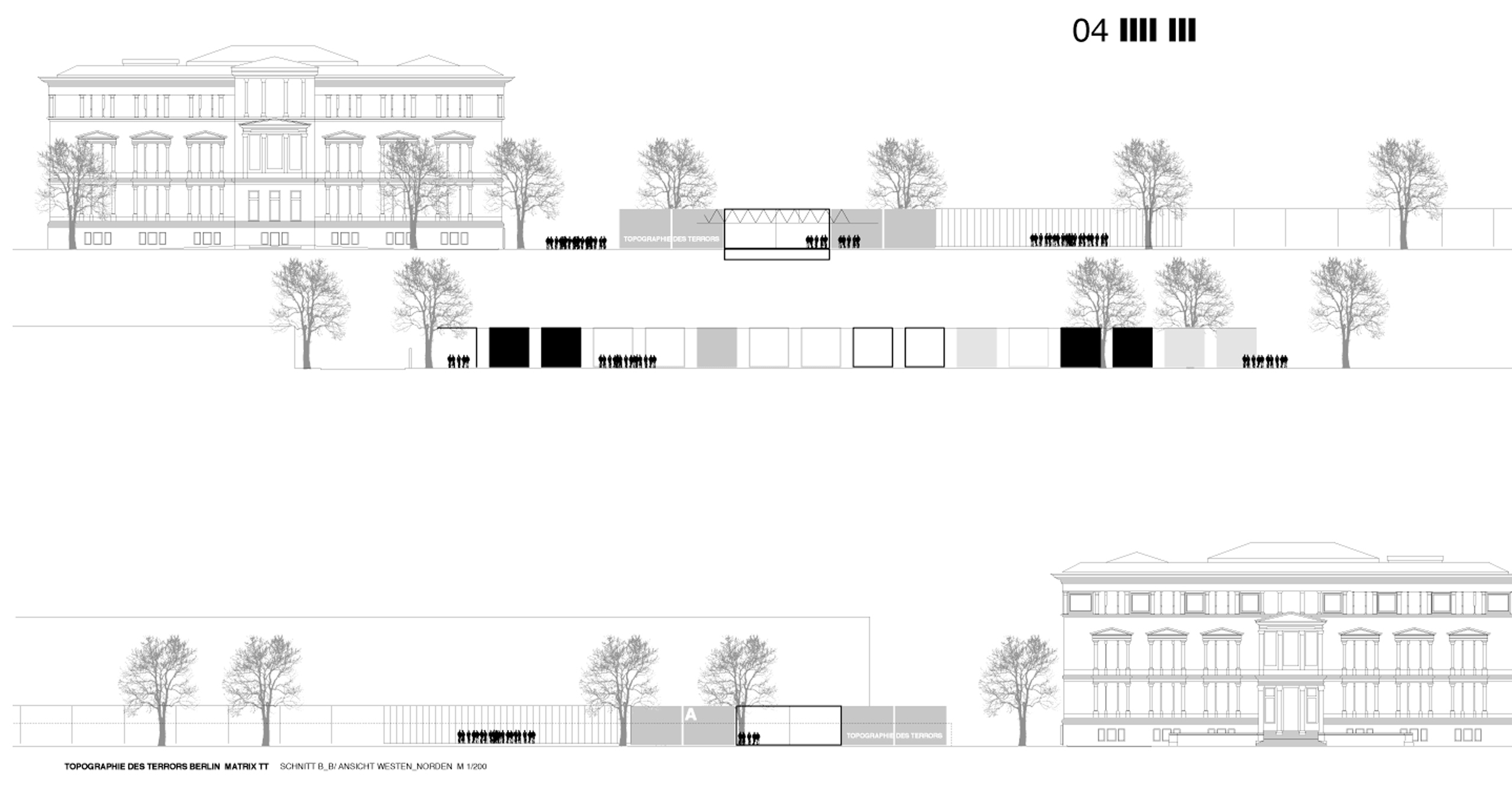

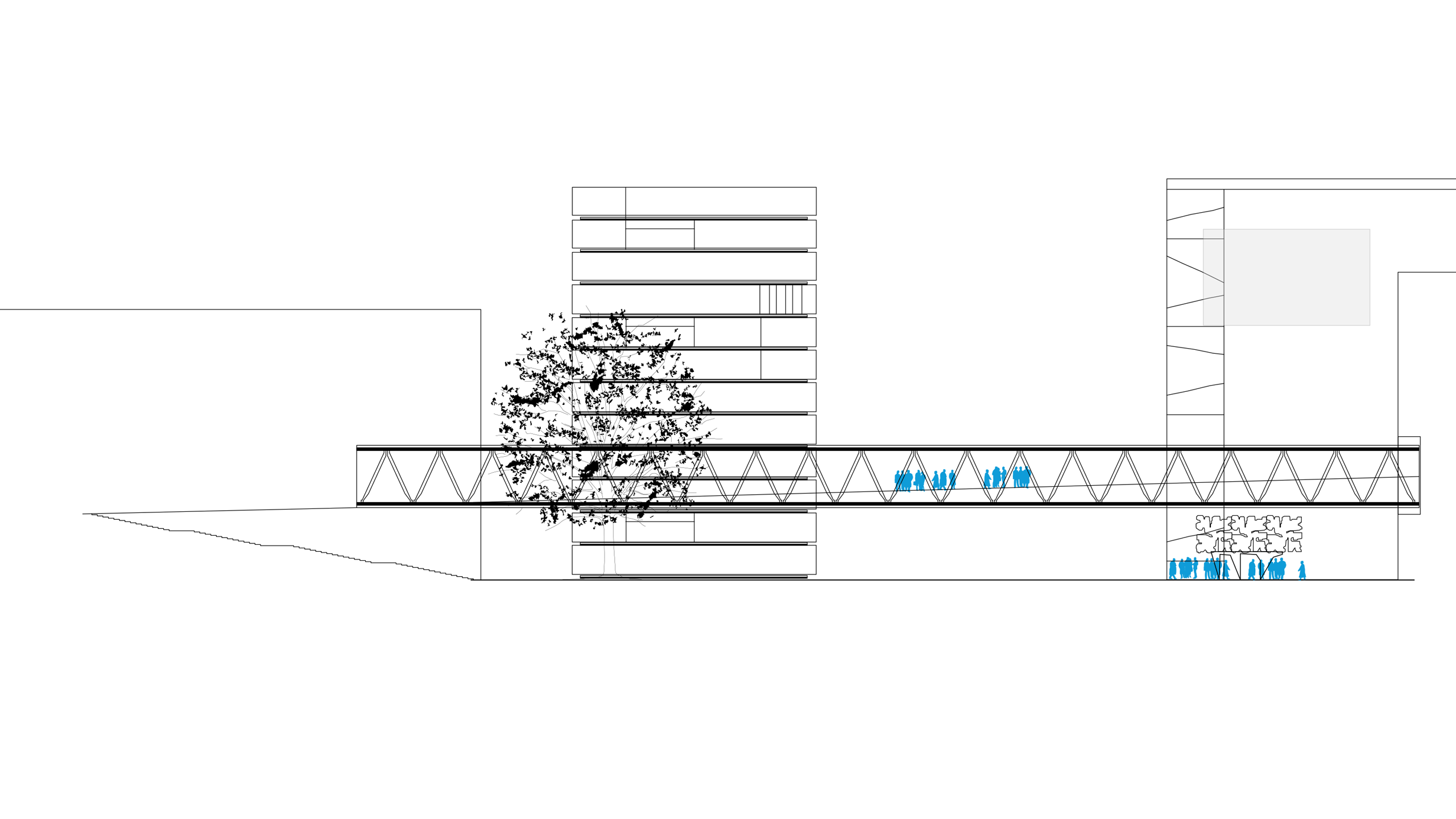

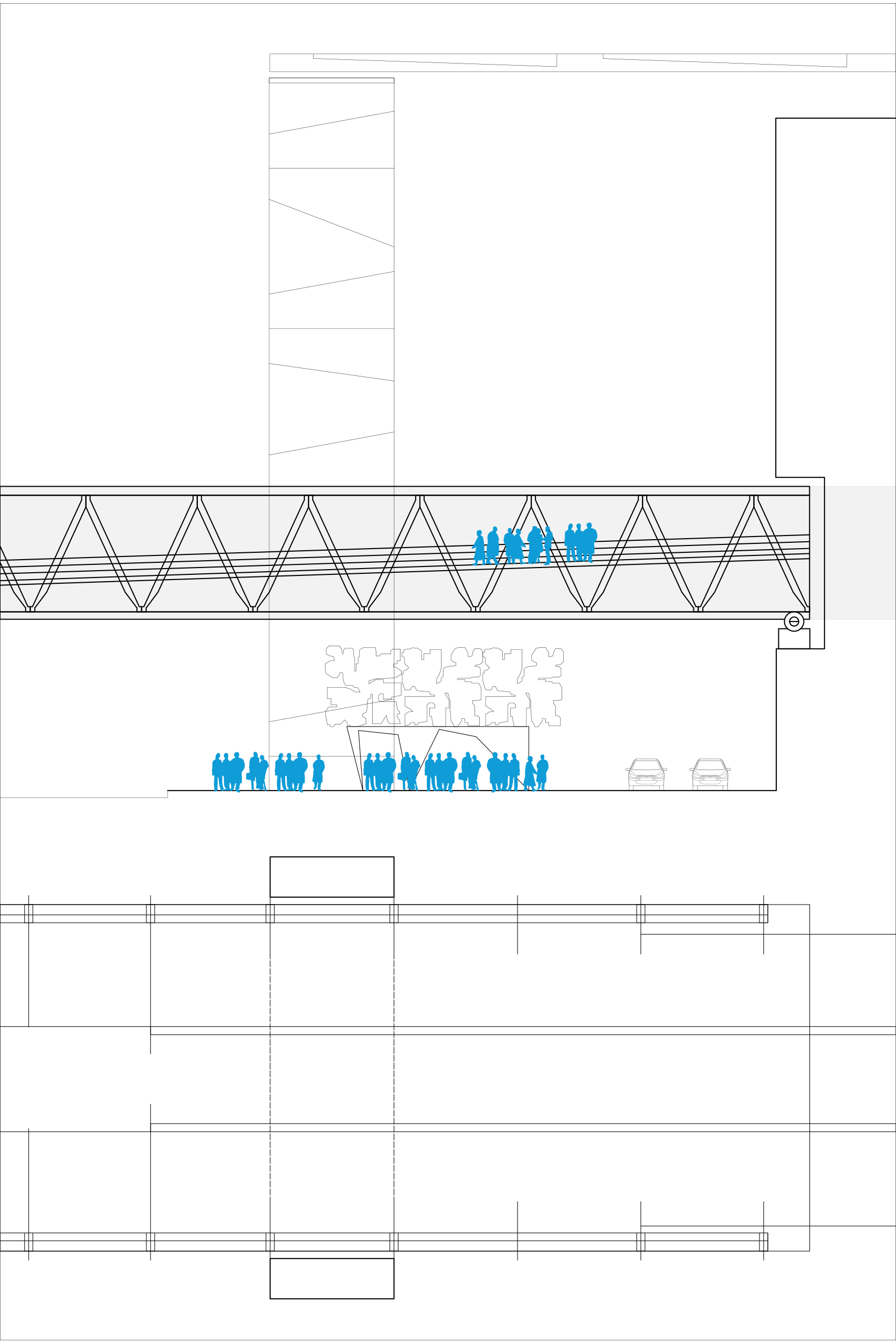

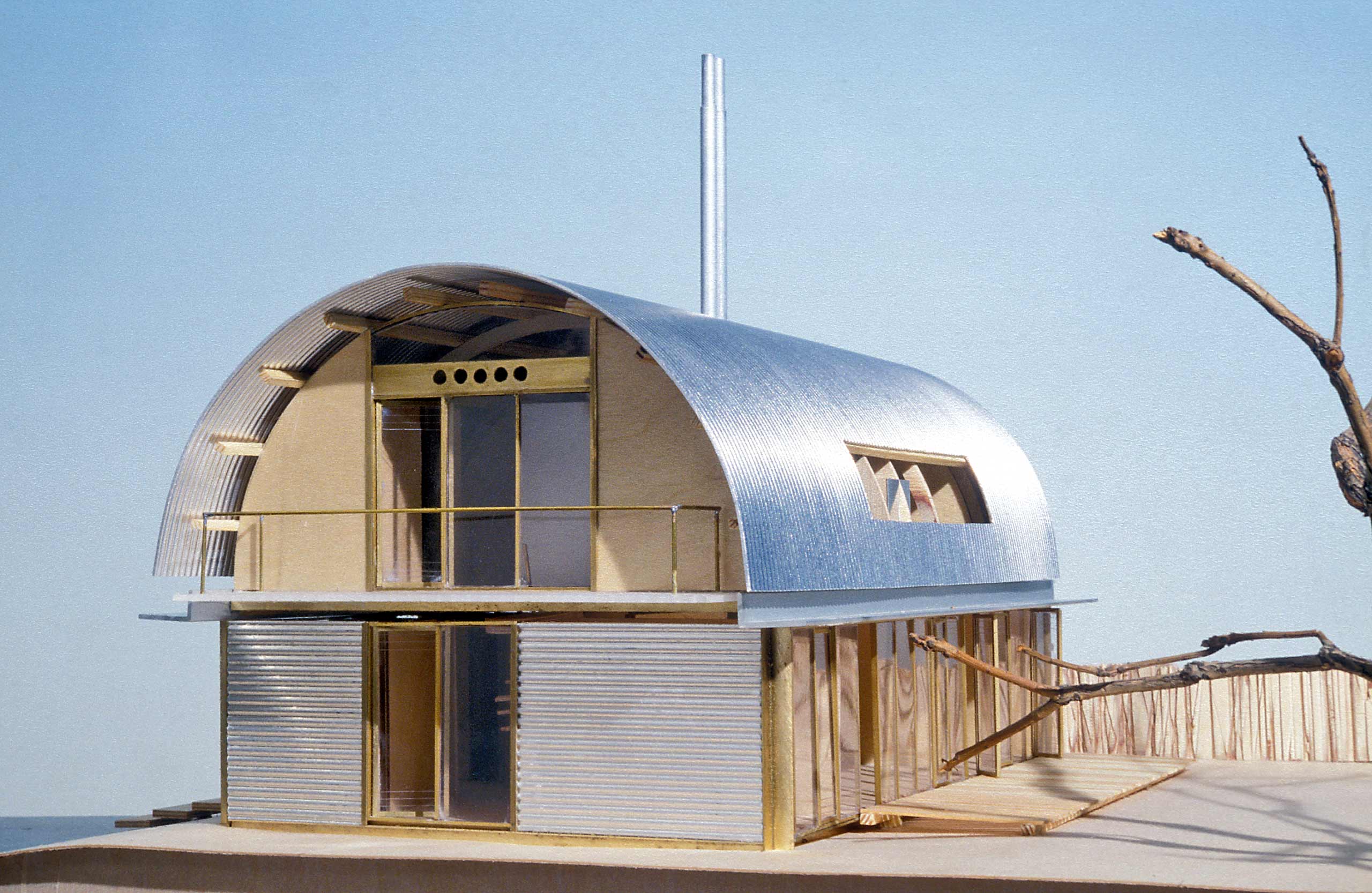

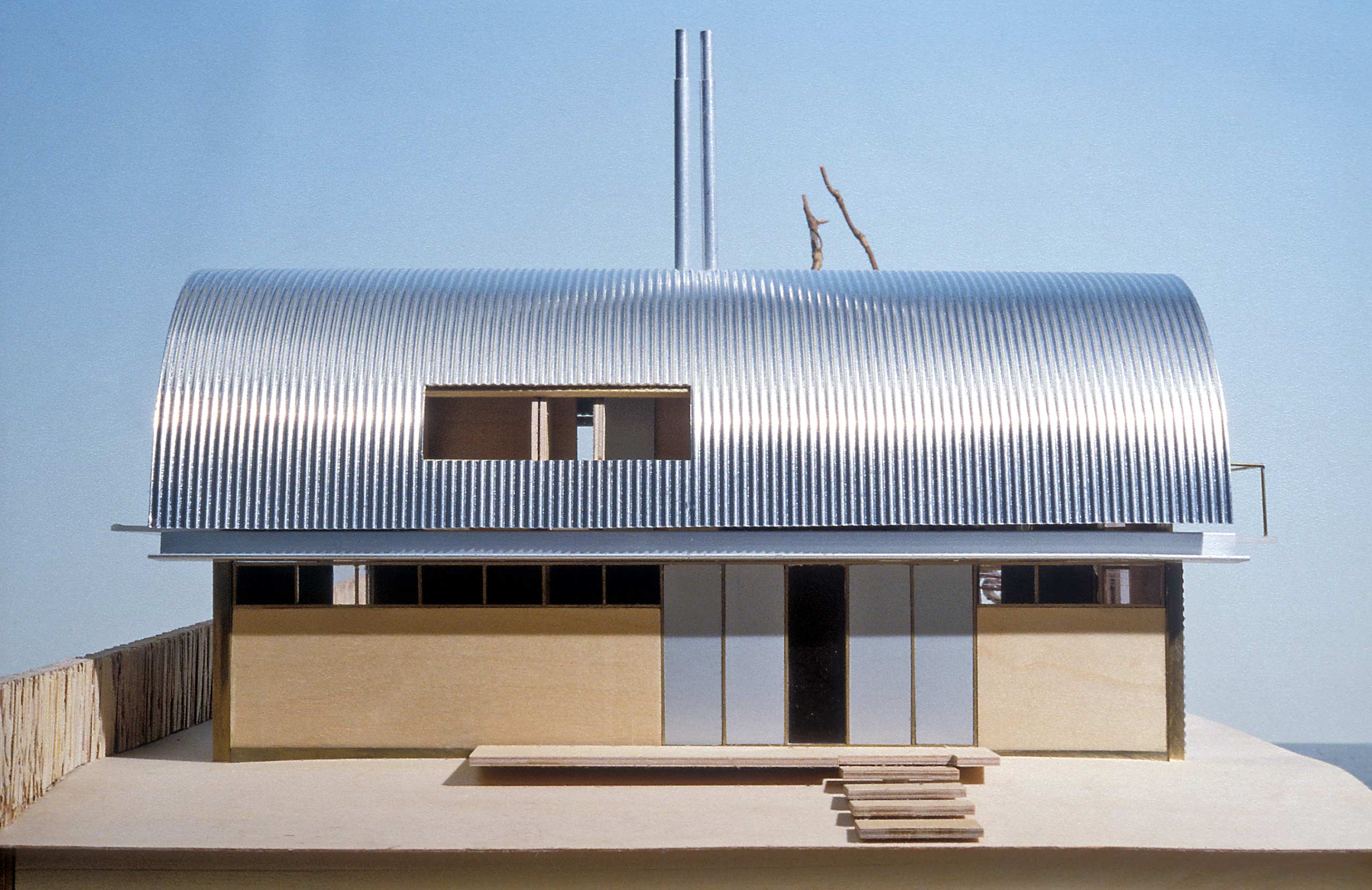

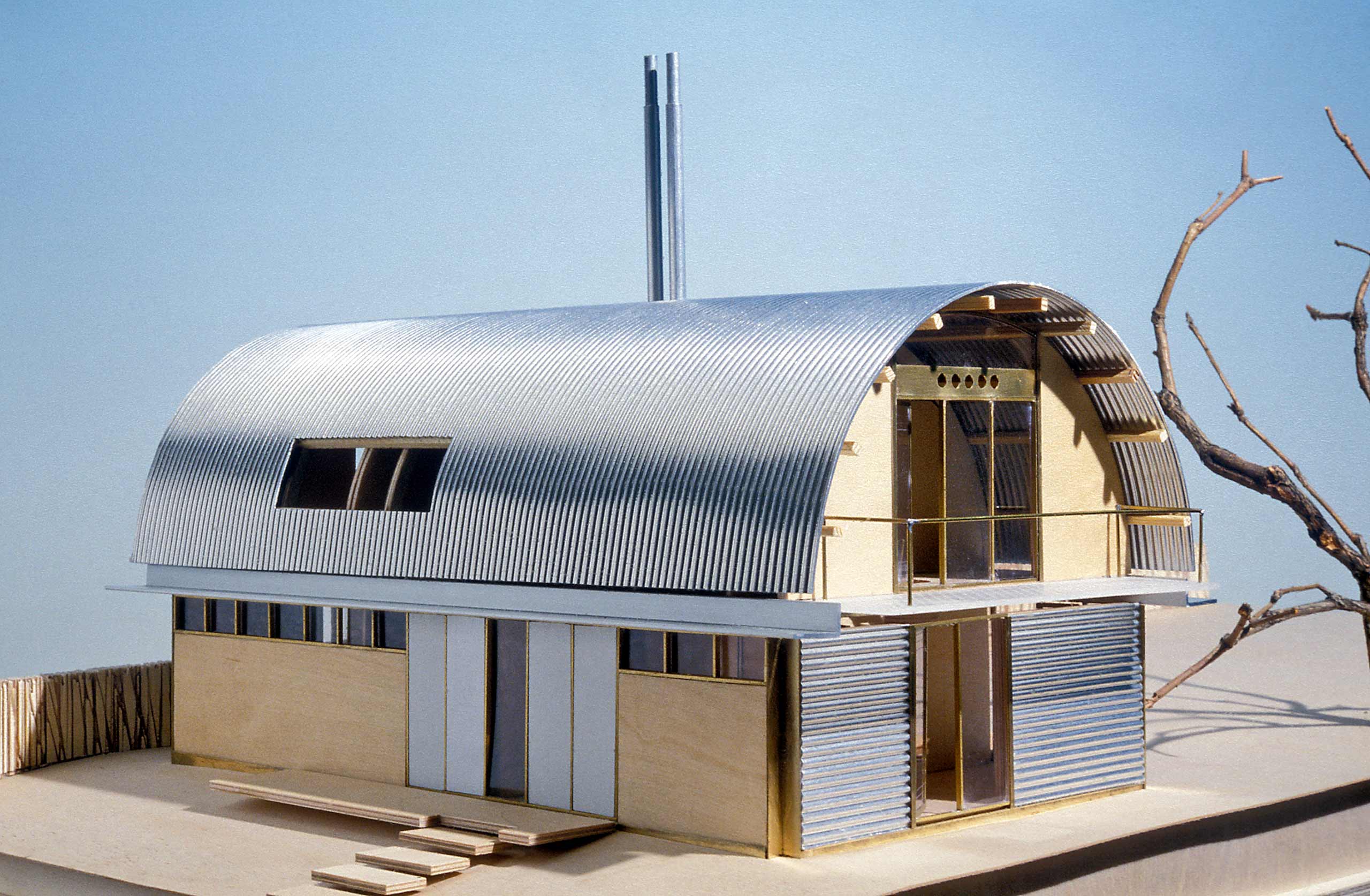

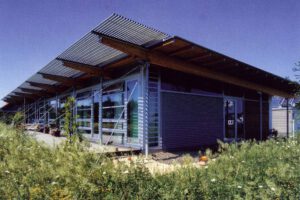

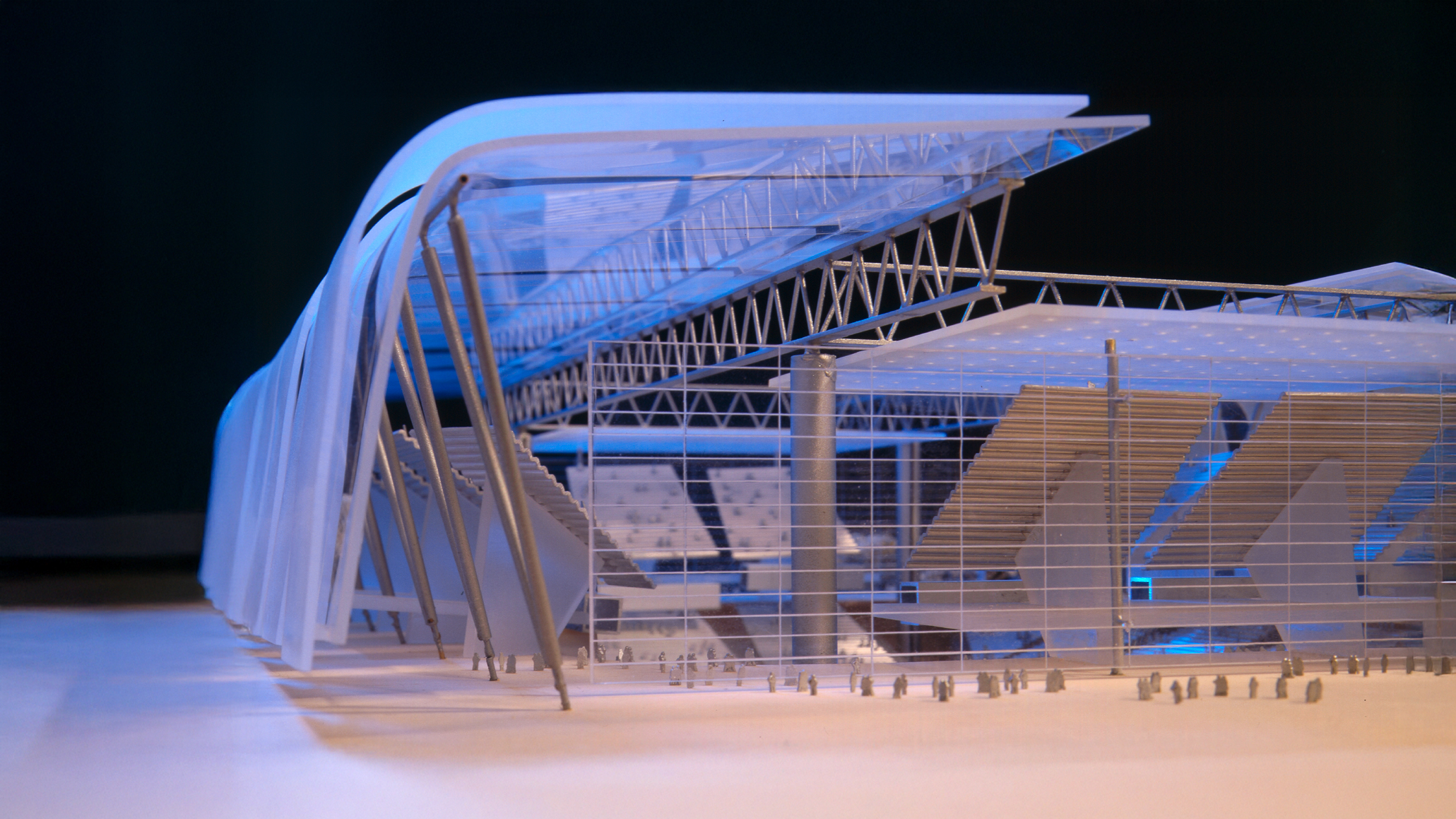

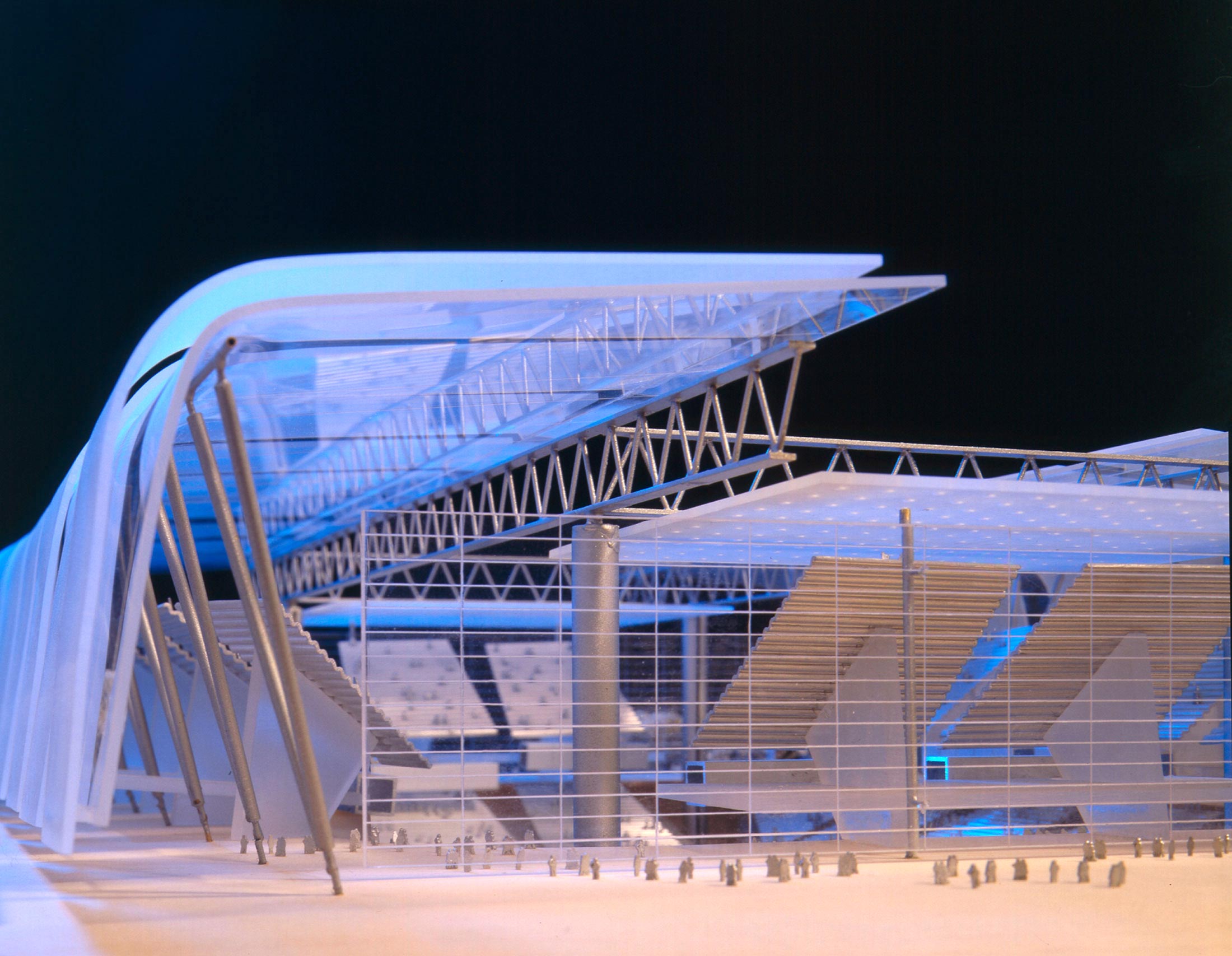

A clearly recognizable ordering system spans the entire site like a grid. Measurement points visualize the structuring of the existing terrain through a light system. Within this grid, the Matrix of TT Berlin develops. The proposed construction is inherently temporary—using steel, manageable dimensions, and bolted structures.

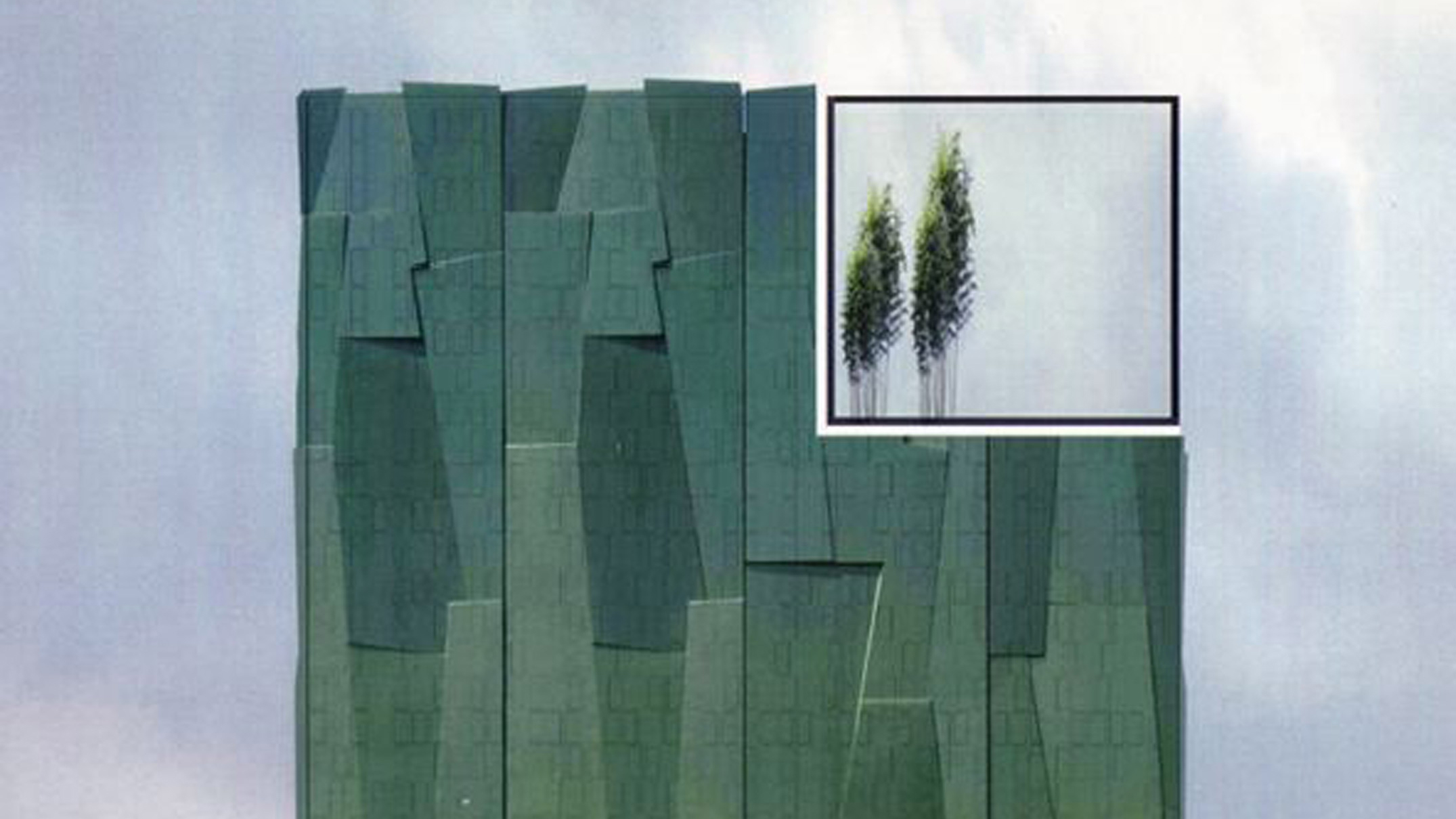

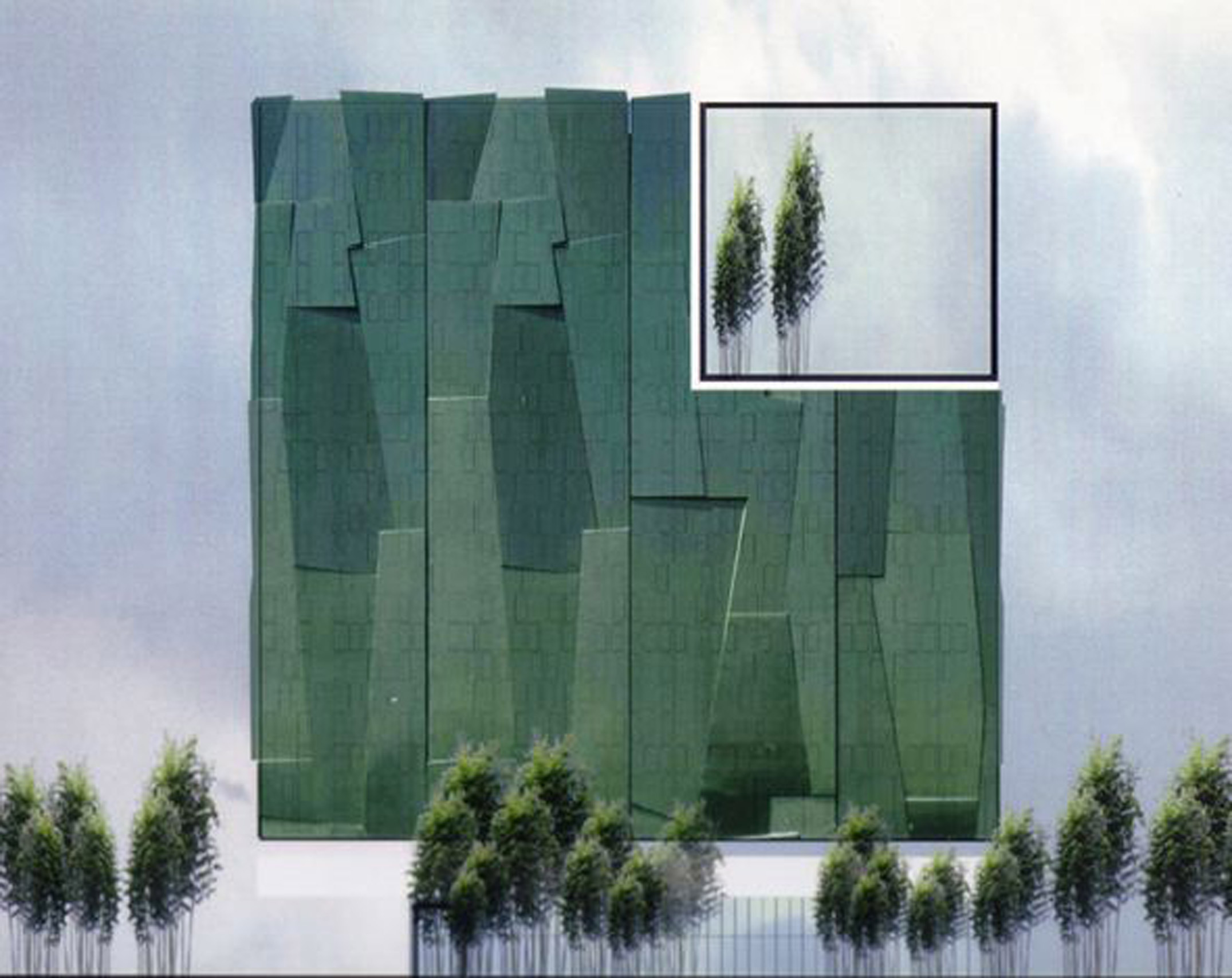

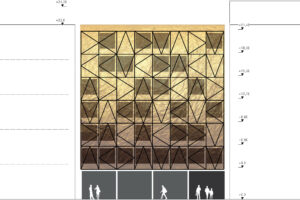

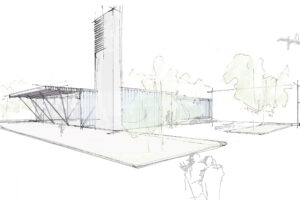

The treatment of the exterior surfaces follows the idea of simple spontaneous vegetation. They are left open to nature. The outdoor exhibition is organized as a path. The edges are sculpturally treated and closed. Instead of a traditional fence, a steel sculpture (Uecker: "Nail Pictures") will control access to the site.

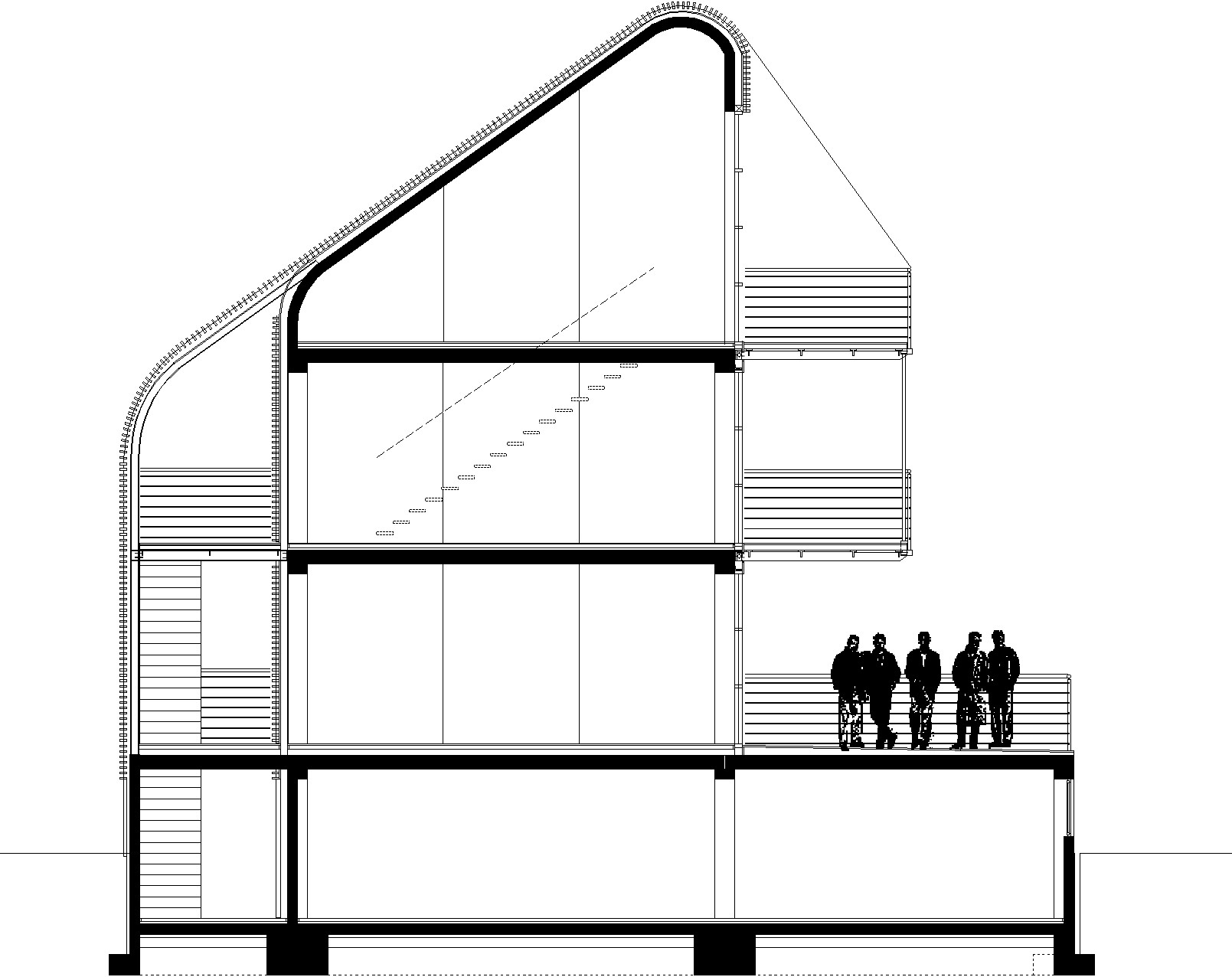

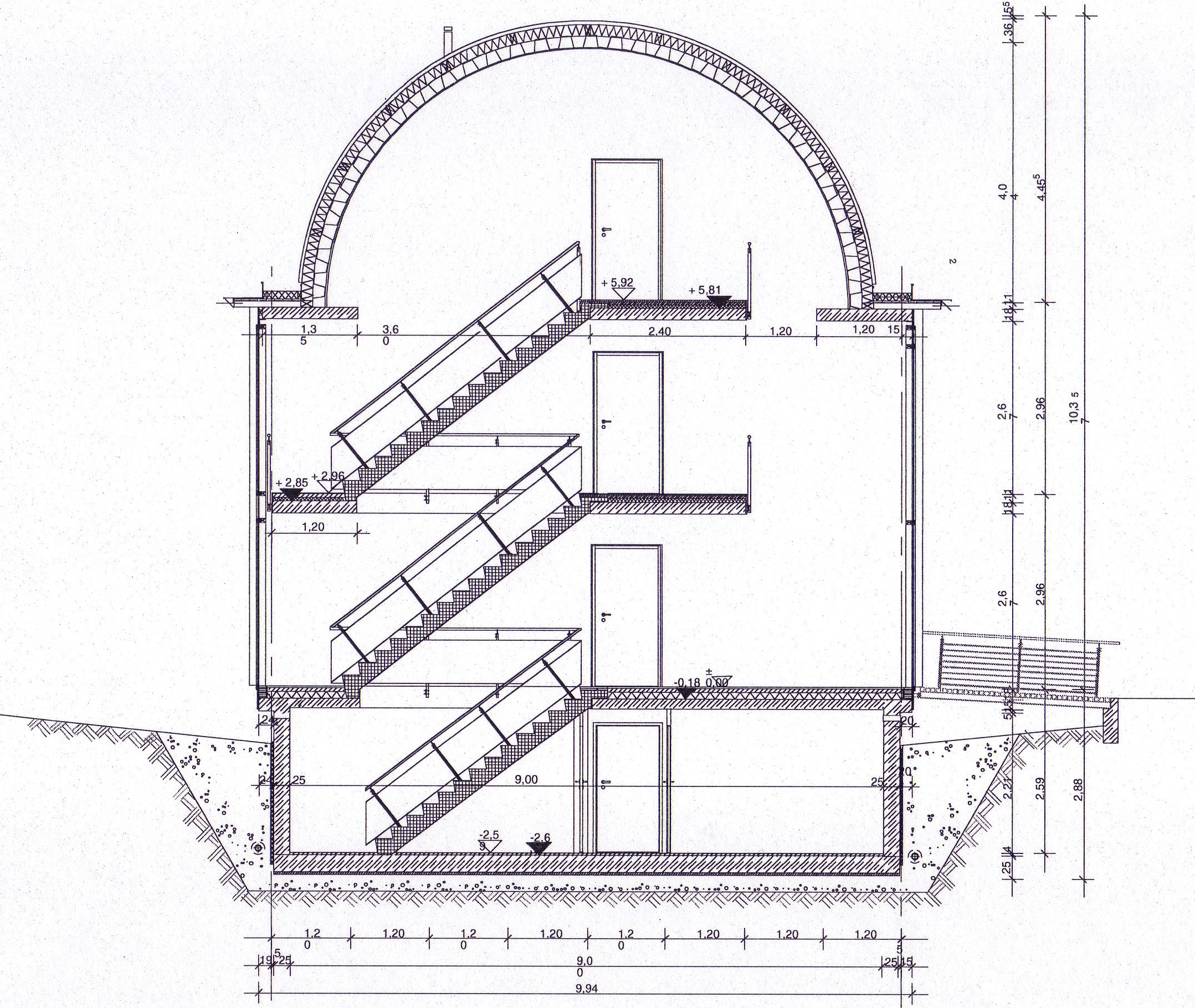

Visitors can enter and exit this "open house" at many points. The program is therefore organized along a linear path that is climate-controlled and allows for easy orientation.

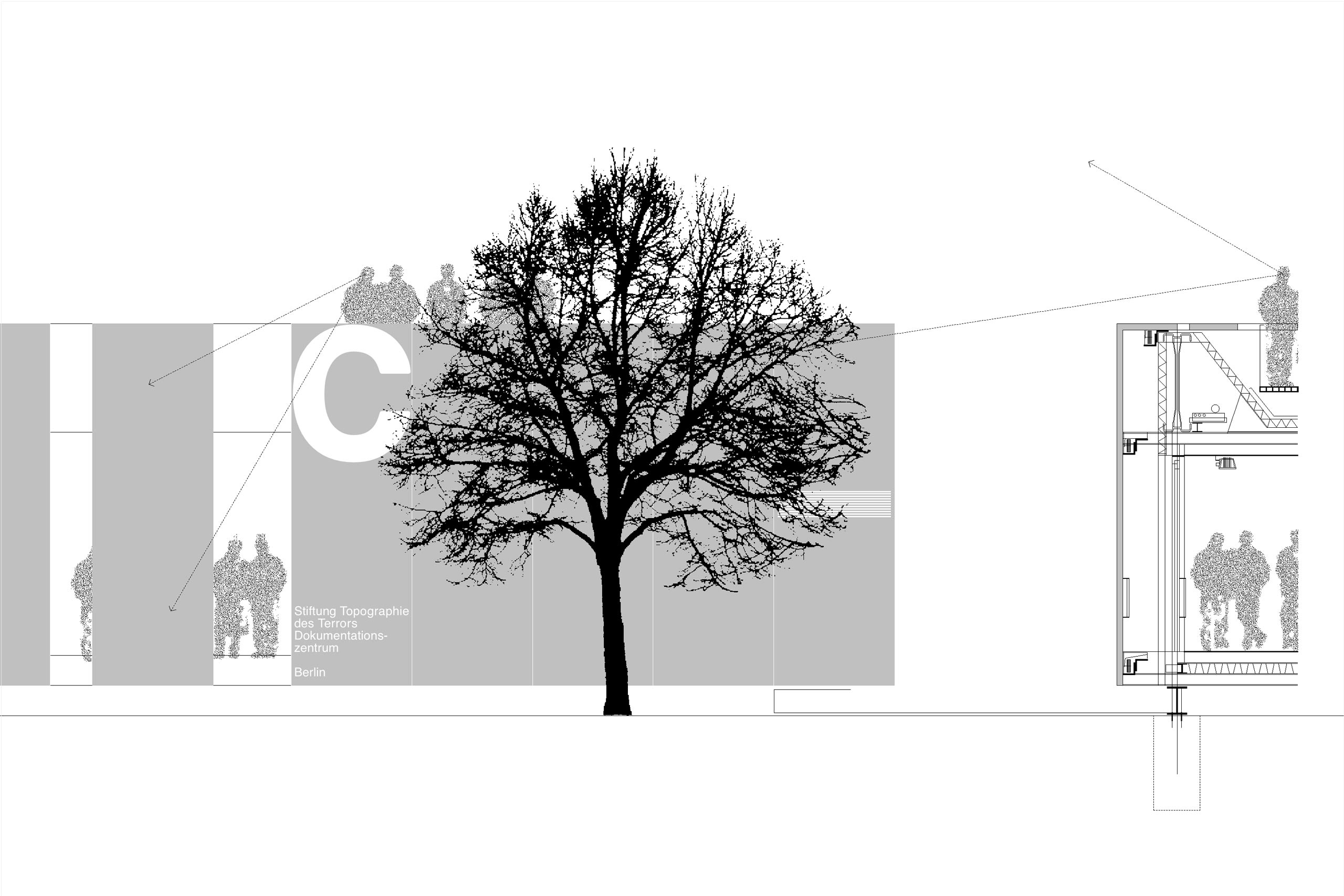

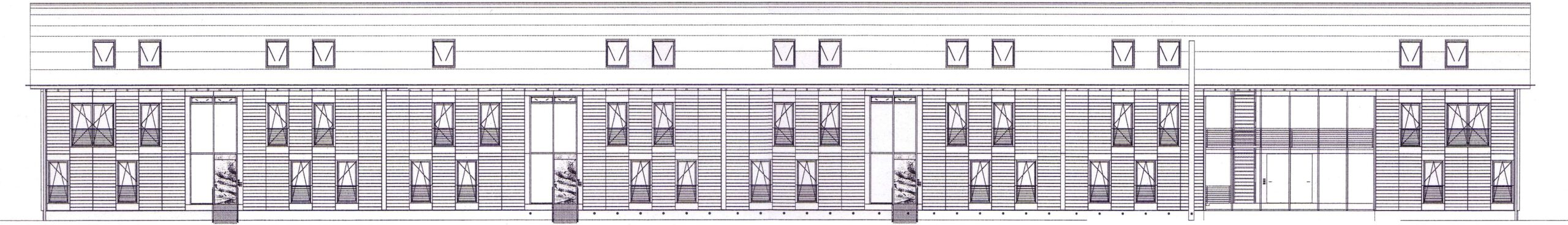

The Martin-Gropius-Bau has been preserved as a significant building and today defines the location through its inherent presence. The proportionality of the new building is derived from the facade of the Martin-Gropius-Bau.

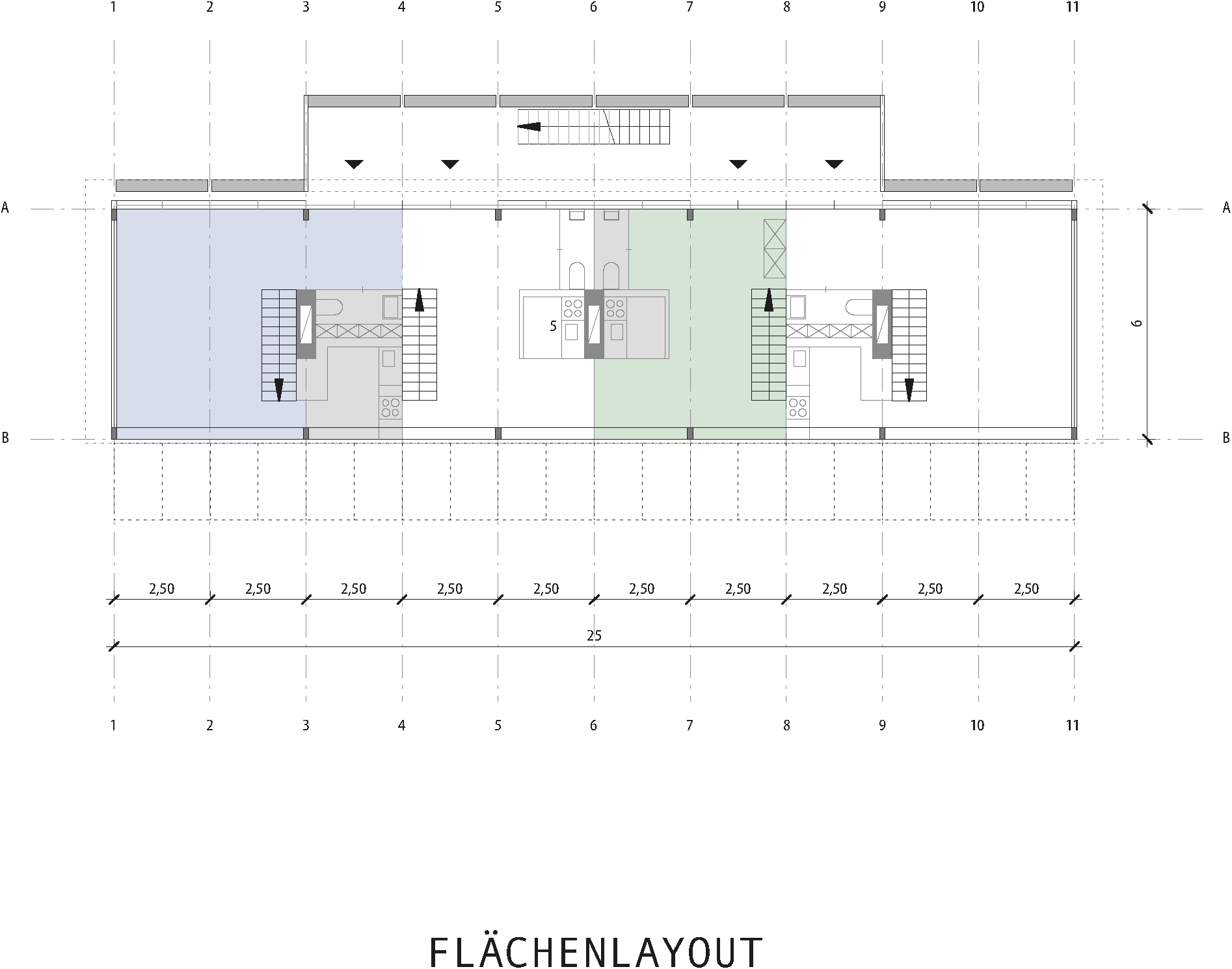

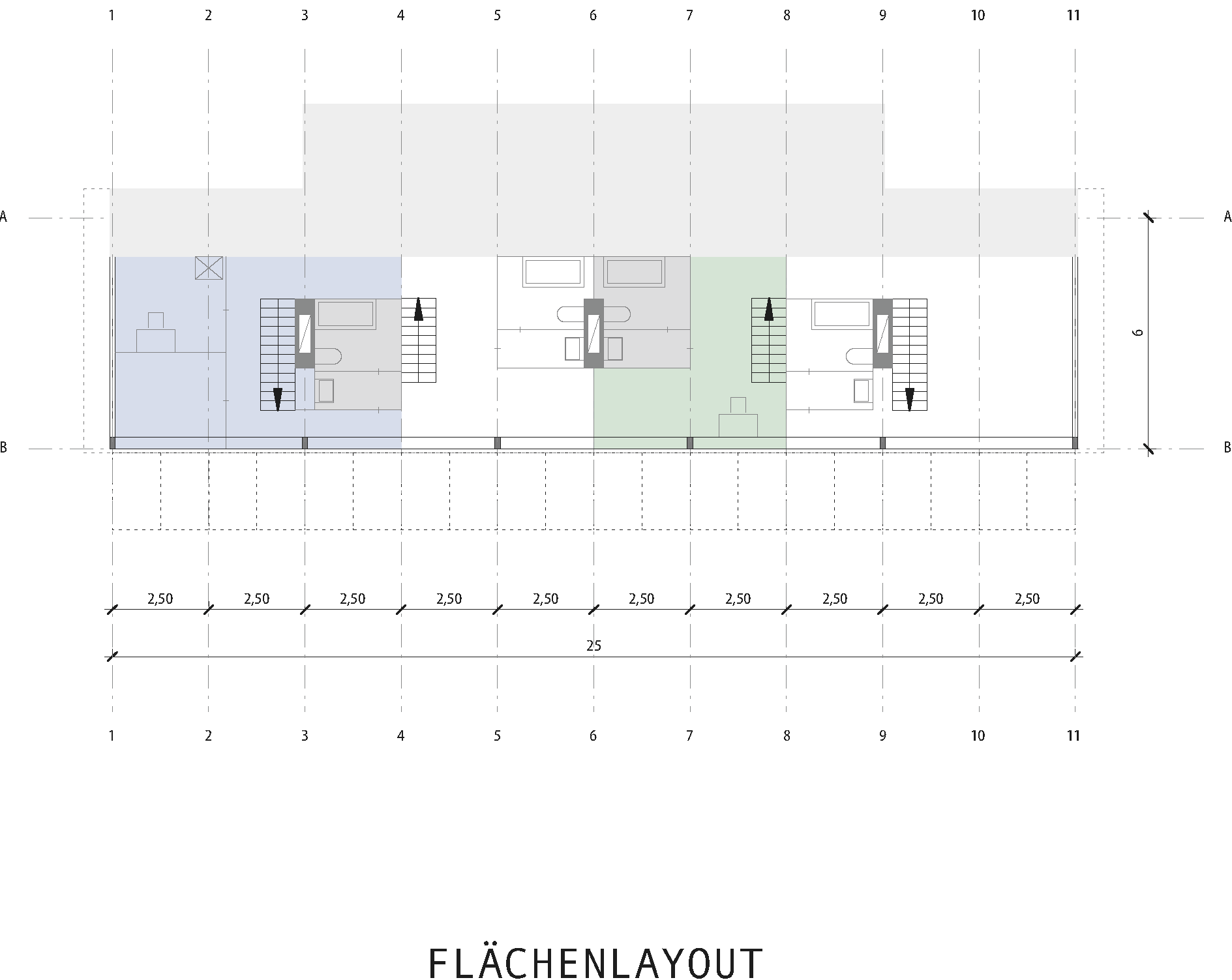

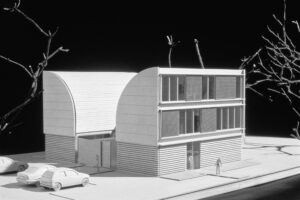

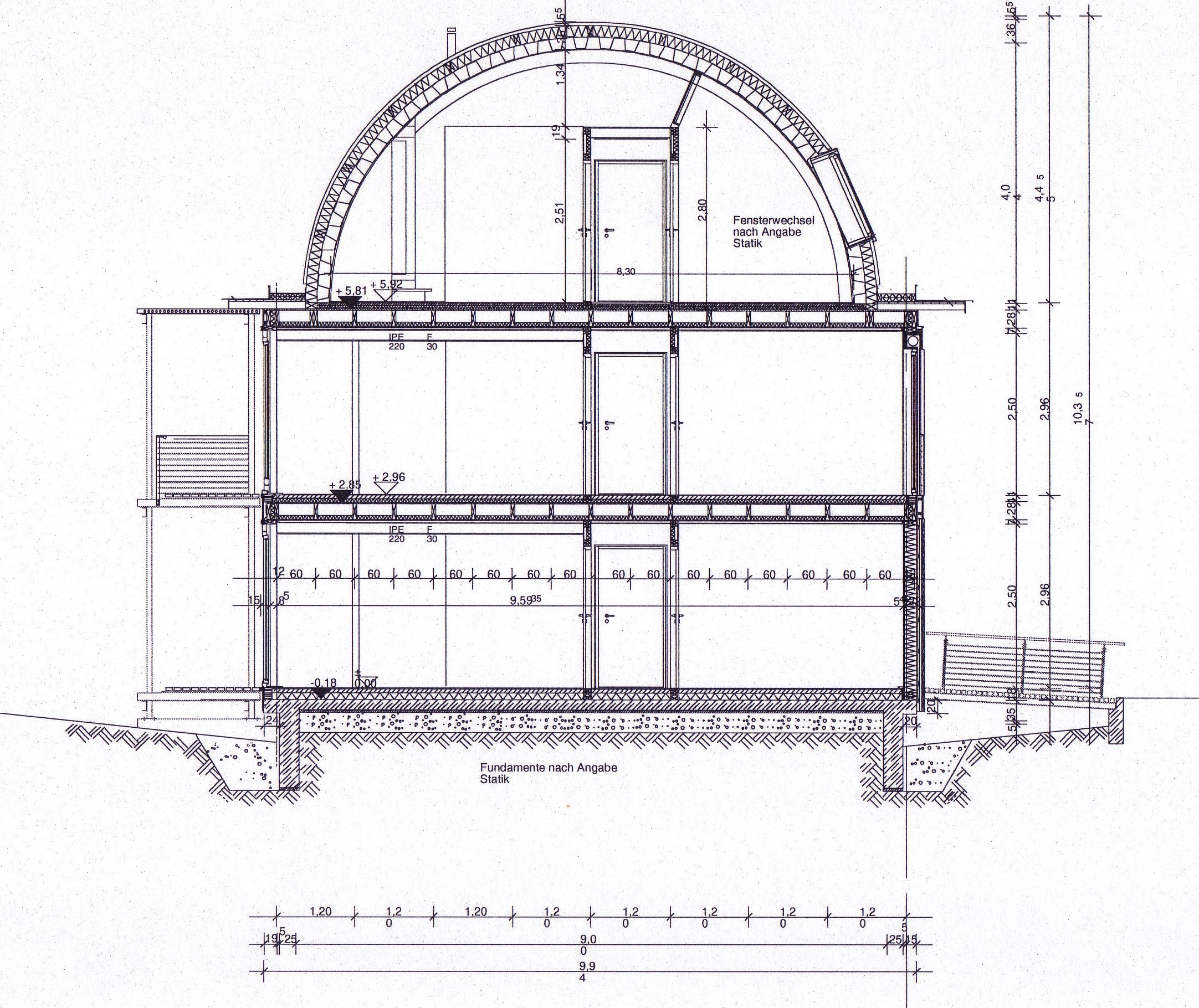

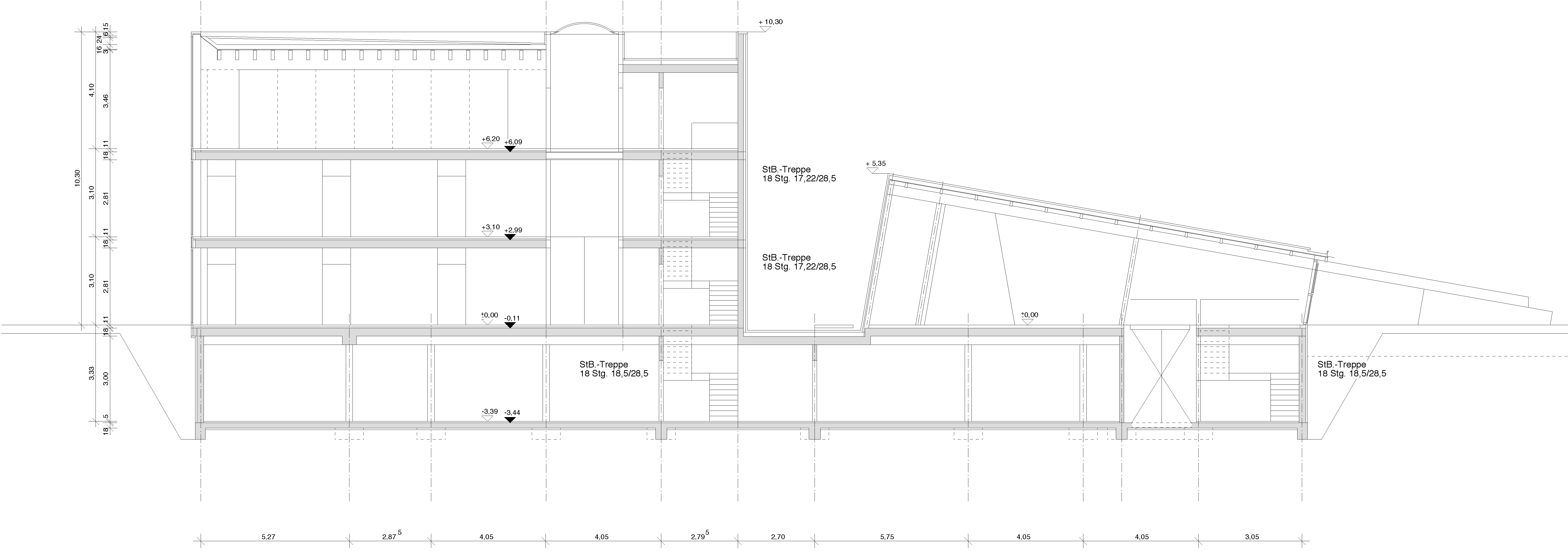

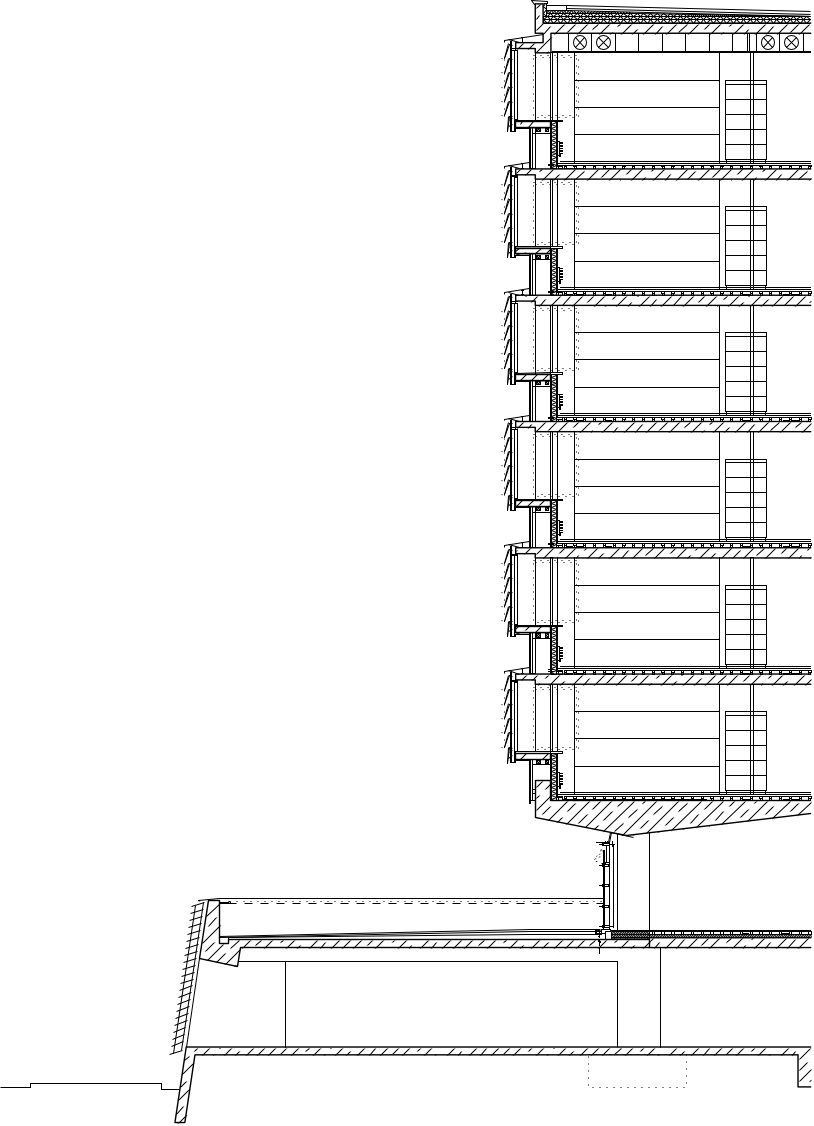

The chosen system is modular. It is not a finished house but is changeable and expandable. It allows for growth or for a more modest and reduced "work in progress." The construction should be maximally reduced and slim. The connection elements—supports, beams, and purlins—are standardized and simple in processing and application.

The energy concept provides for a slim and simultaneously sustainable energy and technical supply. High-quality thermal insulation reduces thermal losses and minimizes the need for building technology. Natural ventilation and exhaust are achieved through a simple exhaust system, which is also used for cooling (night ventilation) in summer.

Single-story construction, high prefabrication, minimal fire protection requirements, small structural dimensions, standardized structural elements, and the possible omission of vertical access cores and elevator systems result in low construction costs. The saved budget is invested in additional space offerings.

Data

Competition

2006

Address

Niederkirchnerstraße 8

10963 Berlin

Awarding Authority

Bundesamt für Bauwesen und Raumordnung;

Stiftung Topographie des Terrors