Airporthotel Berlin

Berlin

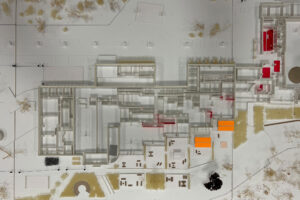

The business center with hotel marks the start of the business park at the nearby new Berlin Brandenburg Willy Brandt Airport. Future users and the neighborhood are unknown at the beginning - the site is an undeveloped field. The path to form therefore leads via sustainable footprints: ecological, economic, social and cultural. The relevant parameters are: urban contours, compactness (optimum A/V ratio), an efficient energy concept, functional user requirements, manufacturing processes, use and flow of materials, life cycle considerations, financing strategies, budget limits, etc. We call this process the “Sudoku strategy” (try & error). Basic geometries - cubes, cuboids, slices, lines, dots - are used to find shapes. They can be organized in a free order, vary in length, width and (storey) height and follow the specifications of the uses that are gradually found. In this way, a systematic collection of coordinated shapes and surfaces is created, which, organized in a meaningful way, depicts a clear configuration at the end of the process.

The result is a house with the required volumes and surfaces. The load-bearing system consists of prefabricated columns and ceiling panels. Like the “domino house” (Le Corbusier), all floor plans are completely variable - the extension is temporary and can be adapted to requirements at any time. All shafts are perpendicular to the façade. The shafts arranged in this way and the horizontal window bands of the façade thus enable unrestricted conversion for third-party use - e.g. as an office building.

Façade

The realization is preceded by an almost three-year planning process until a building application can be submitted. Initially, the client makes an investment decision for this location due to its proximity to the future capital city airport. An urban development concept or a development plan do not yet exist. A competition will be held and will form the basis of the development plan. Users are being sought at the same time. Variants of future building structures are developed, adapted and discarded.

It quickly becomes clear that the building will have to be extremely variable. The uses may change frequently. This makes the planning process itself a critical success criterion: a strategy is required - adaptable and yet clear in its approach. Other parameters must therefore be considered to determine the final appearance. We started by examining various phenomena: Markings in the sky (lines, cloud holes, vistas), global + regional (options of flying), approach + take-off (the play with scale), natural features (nature reserve, birch forest in the neighborhood), technical innovations (development dynamics of aviation technology).

Now façade structures are explored - monolithic, elemental, collaged (glass + concrete), structures, colors, reflections, etc. The decision is made in favour of a horizontal structure that synchronizes the window bands to irritate the viewer. Process-based planning requires an adaptable façade concept - the basic geometries described above are given their actual appearance by a summarizing surface layer: an overall made of steel panels with a defined, summarizing color code. The system is modular and adaptable in planning + construction and creates a structural identity through the color, it is robust, reversible and inexpensive.

Building physics, construction, production and maintenance costs of the façade

The selected system is modular and therefore variable during the planning and construction process. Steel is highly resistant to mechanical stress and is non-combustible due to its material properties (simplified fire protection). Due to its mass, it offers good protection against overheating in summer, increased sound insulation (hotel use) and allows large spans of the façade elements with a minimum number of substructure fixing points. The substructure is based on a multifunctional system strip with concealed fastening, which allows constraint-free and simple plug-in installation. The result is curtain-type, rear-ventilated and permanently flat façades. Temperature influences and construction tolerances are reduced without tension.

The large span width of the façade elements and the minimized substructure (reduction of anchor points) lead to a reduction in thermal bridges. The large span width and large span width of the panels enable shorter installation times and therefore lower installation costs. The minimized number of fixing points reduces heat loss, while the surface coating makes cleaning or maintenance coatings permanently obsolete. The system and façade product thus create a highly cost-effective façade with a cost per square meter of gross floor area that is only slightly higher than that of external thermal insulation composite systems. The surfaces of the raw steel are given a long-lasting finish with a zinc-magnesium alloy. The entire façade system is 100% recyclable + permanently flat façade surfaces.

Color Scheme

What we see is not the shell as the façade of a house, but the “image” of a façade - an abstract composition with which the house eludes a clear classification (building type + use) and instead irritates passers-by and invites them to engage in their own process of abstraction. The color chart provided by the manufacturer did not seem sufficient to achieve this goal. Therefore, additional colors (special colors) were required, which we derived from our coding. The color coating (“matt”) is almost self-cleaning due to its surface structure, UV-stable, non-reflective and color-intensive in all weather conditions and particularly emphasizes the degree of abstraction. The cooperation with Thyssen-Krupp was uncomplicated, supportive and interested at all times - even at a time when the system was new and the costs could not yet be officially calculated.

Data

Completion

2012

Address

Alexander-Meissner-Strasse 1

12526 Berlin

Client

ANH Grundbesitz GmbH

Partner

Tragwerk:

SKP Ingenieure Gmbh

Landschaftsplanung:

Kamel Louafi, Berlin

Haustechnik:

W33, Berlin

Innenarchitektur:

studio aisslinger, Berlin

Fotos:

Jan Bitter, Berlin